NeuralNet

- 24

- 0

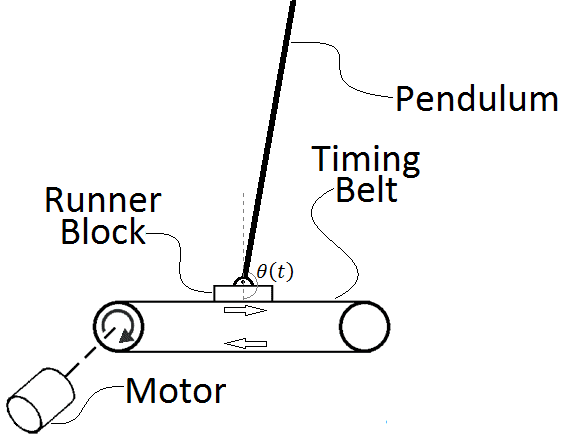

I am trying to stabilize an inverted pendulum with a physical system as follows:

The measured values of the pendlums angle and the cart (runner block) position are sent to a digital controller. The digital controller then outputs a value that is sent to the motor to turn the belt pulley system which in turn moves the cart.

The problem I am having is my equations are such that the value coming out of the controller is the force (in Newtons) that needs to be applied to the cart to move it. I need to convert the force value to the torque value at the motor.

How do I do that?

I am an EE major, and don't know too much about ME stuff. Any help is much appreciated.

The measured values of the pendlums angle and the cart (runner block) position are sent to a digital controller. The digital controller then outputs a value that is sent to the motor to turn the belt pulley system which in turn moves the cart.

The problem I am having is my equations are such that the value coming out of the controller is the force (in Newtons) that needs to be applied to the cart to move it. I need to convert the force value to the torque value at the motor.

How do I do that?

I am an EE major, and don't know too much about ME stuff. Any help is much appreciated.

Last edited: