Timtam

- 40

- 0

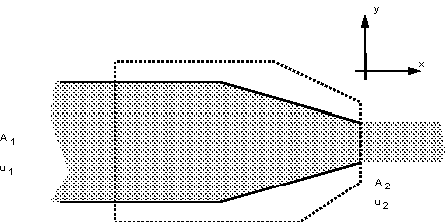

I have been reading many examples of control volume calculations regarding nozzles

They all end up with a reaction force on the nozzle in the direction of the flow.

I can't understand this from a Conservation of momentum perspective.

I can't understand this from a Conservation of momentum perspective.

I would expect that the reaction force, by Newtons third law, would be opposite the mass that was accelerated in. This is how many people explain it but it doesn't equate with the control volume result.

Can anyone review my attempt at a solution and critique

Attempt at a solution

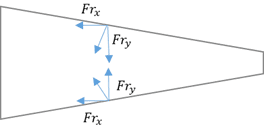

It appears the resultant force has nothing to do with the flow acceleration or pressure drop

Much like the flow around a bend, it is due to the change in flow direction.

More specifically, it is the x direction components of the resultant force due to the angle of the nozzle changing the flows direction.

(Y direction components being equal and opposite directions cancel out.)

Why doesn't the flow "acceleration" require a resultant force?

Even though the velocity of the fluid has increased at the nozzle, the flow has experienced no 'real' acceleration so no resultant force is required.

While the velocity at P2 has increased, the volumetric flow rate Q has not. It has only changed in area and by continuity- velocity has increased.

The x-direction flow rate Q into and out of the control volume is the same - so there is no acceleration.

The pressure gradient force?

The flow rate Q is fully accounted for by the pressure difference P1-P2 over the original area

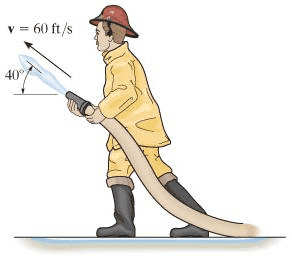

Why do firefighters brace a hose forward ?

I don't think they do I think they actually brace it down.

This is because a hose initially runs along the ground then up the firefighter.

So again there is resultant forces from changing a fluids direction initially up (the resultant force is provided by gravity and against the ground) once it is traveling up to make it horizontal again the firefighter must provide a downward force above the hose to change its direction downward again.

They all end up with a reaction force on the nozzle in the direction of the flow.

I would expect that the reaction force, by Newtons third law, would be opposite the mass that was accelerated in. This is how many people explain it but it doesn't equate with the control volume result.

Can anyone review my attempt at a solution and critique

Attempt at a solution

It appears the resultant force has nothing to do with the flow acceleration or pressure drop

Much like the flow around a bend, it is due to the change in flow direction.

More specifically, it is the x direction components of the resultant force due to the angle of the nozzle changing the flows direction.

(Y direction components being equal and opposite directions cancel out.)

Why doesn't the flow "acceleration" require a resultant force?

Even though the velocity of the fluid has increased at the nozzle, the flow has experienced no 'real' acceleration so no resultant force is required.

While the velocity at P2 has increased, the volumetric flow rate Q has not. It has only changed in area and by continuity- velocity has increased.

The x-direction flow rate Q into and out of the control volume is the same - so there is no acceleration.

The pressure gradient force?

The flow rate Q is fully accounted for by the pressure difference P1-P2 over the original area

Why do firefighters brace a hose forward ?

I don't think they do I think they actually brace it down.

This is because a hose initially runs along the ground then up the firefighter.

So again there is resultant forces from changing a fluids direction initially up (the resultant force is provided by gravity and against the ground) once it is traveling up to make it horizontal again the firefighter must provide a downward force above the hose to change its direction downward again.

Last edited: