- #1

awaiting

- 24

- 0

Hi everyone,

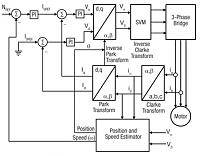

I am trying to implement the current control (Id, Iq) of a four pole PM synchronous motor. I am having trouble in making the Iq current follow a set reference.

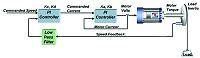

I had also implemented a cascaded speed control for a dc motor.

In that case, I adjusted the gains of the PI controller (inner loop/current loop) by stalling the motor and checked if the motor current followed the set reference current. It worked in this way for the dc motor. I thought of doing the same way for Iq but I am not getting the expected results.

In delta configuration of the stator, if I make the integral gain to be zero, the motor does not rotate. The motor starts rotating if I increase the integral gain to 1 and the speed increases as I increase the integral gain and reaches the maximum value depending upon the supply voltage.

If I stall the motor at different speeds, I get different values of Iq, say for 30 rad/s I have a current of 30mA and 60 rad/s, it is 50mA.

The motor current (Iq) is not following the reference current for any change I am making in the Kp and Ki values

Is there any other approach to achieve the PI control for both the currents?

Thanks

I am trying to implement the current control (Id, Iq) of a four pole PM synchronous motor. I am having trouble in making the Iq current follow a set reference.

I had also implemented a cascaded speed control for a dc motor.

In that case, I adjusted the gains of the PI controller (inner loop/current loop) by stalling the motor and checked if the motor current followed the set reference current. It worked in this way for the dc motor. I thought of doing the same way for Iq but I am not getting the expected results.

In delta configuration of the stator, if I make the integral gain to be zero, the motor does not rotate. The motor starts rotating if I increase the integral gain to 1 and the speed increases as I increase the integral gain and reaches the maximum value depending upon the supply voltage.

If I stall the motor at different speeds, I get different values of Iq, say for 30 rad/s I have a current of 30mA and 60 rad/s, it is 50mA.

The motor current (Iq) is not following the reference current for any change I am making in the Kp and Ki values

Is there any other approach to achieve the PI control for both the currents?

Thanks