- #1

Mechstudent

- 2

- 0

Hi;

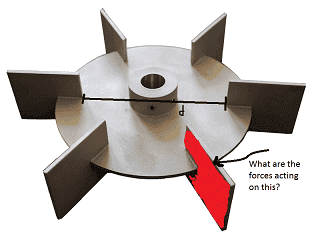

In one of my projects I need a Rushton impeller to be used for mixing applications.

However, these kinds of impellers are quite expensive(400$ for a 2inch impeller) if bought from laboratories equipment manufacturers.

The price tag would be fine with me if only one blade was needed, but this is not the case, as my project involves many small units(around 15-20), totaling over 6000$ just for the blades, if we exclude shafts,motors,coupling and etc..

Hence why i'd like to make "Homemades" impellers. Problem is, I can't quite figure how to calculate the torque caused by the liquid on the blades.

Here's the known informations:

-The impeller is placed inside a cylindrical tank

-We know the diameter/heigth of the tank(let's assume D:10cm and H:20cm)

-The viscosity of the liquid is known(suppose 35cp)

-The RPM of the shaft(Ajustable between 0 to 250 rpm)

-The position of the impeller from the bottom of the tank(5 cm)

What I'd need to calculate is the forces acting on the impellers blade to find the proper length x heigth x thickness to properly mix the liquid(They don't bend or break)

The small diameter d on the picture and the dimensions of the blades are to be chosen;

In one of my projects I need a Rushton impeller to be used for mixing applications.

However, these kinds of impellers are quite expensive(400$ for a 2inch impeller) if bought from laboratories equipment manufacturers.

The price tag would be fine with me if only one blade was needed, but this is not the case, as my project involves many small units(around 15-20), totaling over 6000$ just for the blades, if we exclude shafts,motors,coupling and etc..

Hence why i'd like to make "Homemades" impellers. Problem is, I can't quite figure how to calculate the torque caused by the liquid on the blades.

Here's the known informations:

-The impeller is placed inside a cylindrical tank

-We know the diameter/heigth of the tank(let's assume D:10cm and H:20cm)

-The viscosity of the liquid is known(suppose 35cp)

-The RPM of the shaft(Ajustable between 0 to 250 rpm)

-The position of the impeller from the bottom of the tank(5 cm)

What I'd need to calculate is the forces acting on the impellers blade to find the proper length x heigth x thickness to properly mix the liquid(They don't bend or break)

The small diameter d on the picture and the dimensions of the blades are to be chosen;