Saladsamurai

- 3,009

- 7

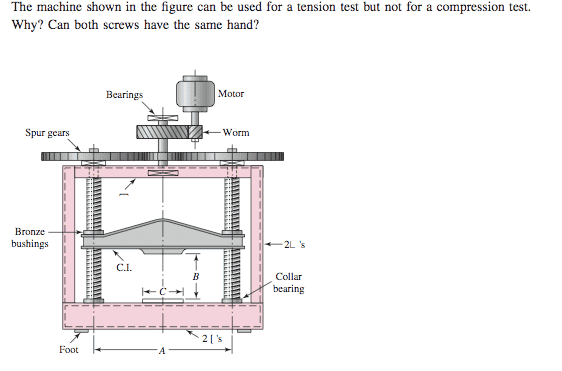

I was reading through some examples in my Design text when I came across this one.

This was their solution:

This was their solution:

I am not sure that I completely follow it. Can someone help shed some light on what's going on here?

I am assuming that the specimen to be put under tension goes where the "B" dimension is right?

I am not sure that I completely follow it. Can someone help shed some light on what's going on here?

I am assuming that the specimen to be put under tension goes where the "B" dimension is right?