- #1

bpaliwal

- 2

- 0

I am struggling through a problem in one of my designs and would appreciate some help.

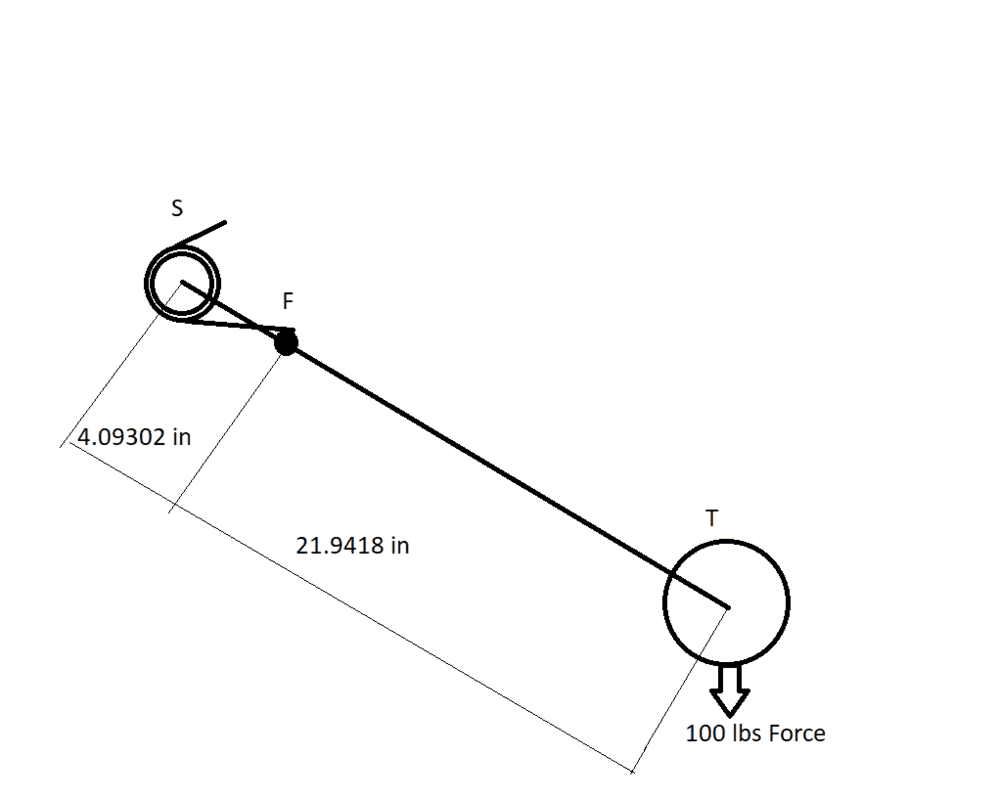

Please refer to the image attached.

Problem Description:

S = Torsion spring

F = fixed point

T = tire

A tire is attached to a torsion spring through an arm as shown in the image. The torsion spring has one end connected to a fixed wall and the other connected to the arm S-T at point F.

How much spring rate (lbs-in/degree) should be there on the spring S, so that the tire T is subjected to a force of 100lbs in the downward direction before any deflection occurs in the spring?

Also, I forgot to mention in the image the angle of S-T with the horizontal is 33.127 degrees.

Any help would be appreciated.

Please refer to the image attached.

Problem Description:

S = Torsion spring

F = fixed point

T = tire

A tire is attached to a torsion spring through an arm as shown in the image. The torsion spring has one end connected to a fixed wall and the other connected to the arm S-T at point F.

How much spring rate (lbs-in/degree) should be there on the spring S, so that the tire T is subjected to a force of 100lbs in the downward direction before any deflection occurs in the spring?

Also, I forgot to mention in the image the angle of S-T with the horizontal is 33.127 degrees.

Any help would be appreciated.