Monkey

- 9

- 0

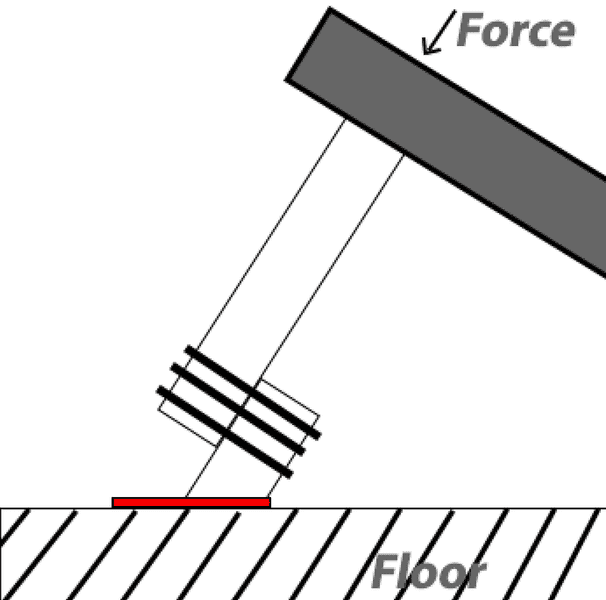

I had a piece of box section steel tubing, 400mm long, 5 x 10cm section, 3mm thick. It has a foot welded to the bottom which stabilises it at the floor (this is in red). It is a weight lifting bench.

I needed to shorten the length, so I cut it in two and overlapped a join, then fixed it with 3 x 14mm Bolts. I have attached a screenshot of what I have done. According to what information I can find on bolts they are capable of a proof load of more than 5000KG (M12 are 4890, M6 are 9100KG - I couldn't find data for 14mm).

How can I work out the load which can be applied to the bolts before they will fail? I´m thinking that the bolts are more than capable of holding the box section together and that in reality the box section would probably crease/bend before the bolts ever snapped.

I needed to shorten the length, so I cut it in two and overlapped a join, then fixed it with 3 x 14mm Bolts. I have attached a screenshot of what I have done. According to what information I can find on bolts they are capable of a proof load of more than 5000KG (M12 are 4890, M6 are 9100KG - I couldn't find data for 14mm).

How can I work out the load which can be applied to the bolts before they will fail? I´m thinking that the bolts are more than capable of holding the box section together and that in reality the box section would probably crease/bend before the bolts ever snapped.