- #1

delsloww88

- 15

- 0

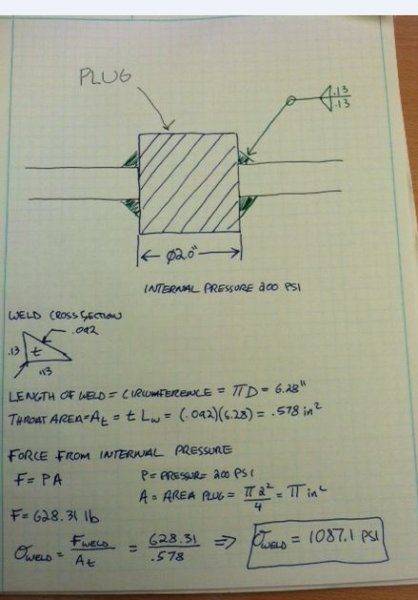

I need someone to tell me if I am approaching this in the right way. In my diagram I tried to show a section view of a wall of a pressure vessel with a cylindrical plug welded into a hole in that wall. I am trying find the stress on the welds in question. This is a small part of a larger project I am working on for school, I am just trying to figure out if my approach is right. See my attempt below. Thank you.