- #1

Trainee28

- 9

- 0

Hello,

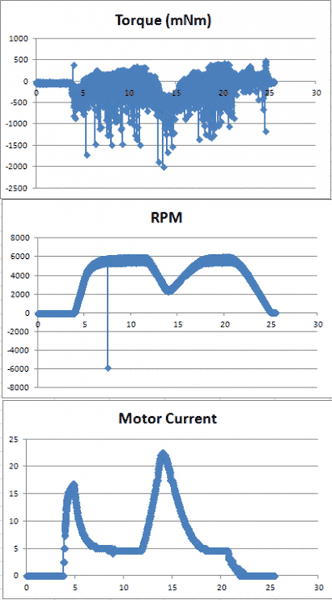

I have a three phase brushless motor and was trying to measure its torque and speed using a torque sensor. The motor will first go to its maximum speed which is about 6000RPM, then I applied a brake to decrease its velocity. Here is what I get as a result of data acquisition :

The problem is that the torque signal looks kinda mess up. I wish to get a signal as nice as the RPM. Does anyone know how can this be done? Some kind of signal processing steps?

Please help me.

I have a three phase brushless motor and was trying to measure its torque and speed using a torque sensor. The motor will first go to its maximum speed which is about 6000RPM, then I applied a brake to decrease its velocity. Here is what I get as a result of data acquisition :

The problem is that the torque signal looks kinda mess up. I wish to get a signal as nice as the RPM. Does anyone know how can this be done? Some kind of signal processing steps?

Please help me.