V8KILR

- 4

- 0

I'm converting my turbo system from a single turbo to a sequential twin turbo system. Where the two turbos intercooler pipes join, the flow from the first turbo to spool can easily reverse back through the second turbo to spool, unless you have a one way valve like a swing check valve to stop this happening.

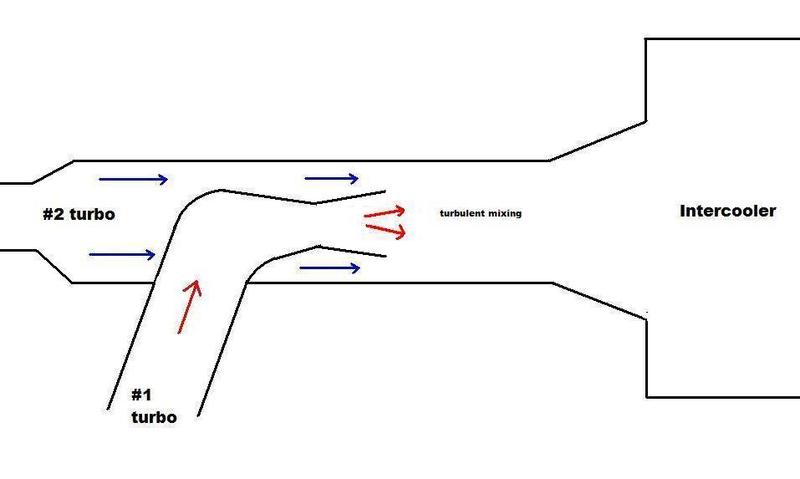

What I would like to do is eliminate the swing check valve by using an air ejector design with the first turbo's intercooler pipe to stop the flow reversing back through the second turbo's intercooler pipe. Here is a diagram I have done.

Could this design work such that at all stages of both turbos boost from vacuum to full boost, there would be no flow backwards to the second turbo?

What I would like to do is eliminate the swing check valve by using an air ejector design with the first turbo's intercooler pipe to stop the flow reversing back through the second turbo's intercooler pipe. Here is a diagram I have done.

Could this design work such that at all stages of both turbos boost from vacuum to full boost, there would be no flow backwards to the second turbo?

Last edited: