ddddd28

- 73

- 4

Hello,

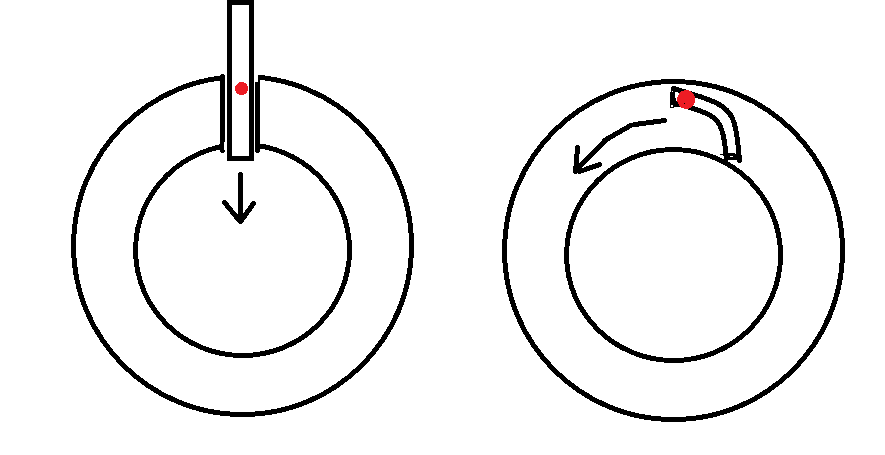

I am trying to design a mechanism that moves a piece towards the center of a disk by rotating a second disk as described in the picture below.

There is a stationary disk which restricts the motion of the piece, so it can move vertically only. There is also a second disk that it is located on the first one and it can rotate. As it rotates, it pushes the red pin and causes to the vertical motion of the piece. So far in theory.

I am struggling to figure out what is the right track of the second disk, or any track will go?

I am trying to design a mechanism that moves a piece towards the center of a disk by rotating a second disk as described in the picture below.

There is a stationary disk which restricts the motion of the piece, so it can move vertically only. There is also a second disk that it is located on the first one and it can rotate. As it rotates, it pushes the red pin and causes to the vertical motion of the piece. So far in theory.

I am struggling to figure out what is the right track of the second disk, or any track will go?