IAMJackal

- 1

- 1

Have built a 55 gallon DIY steamer from a DE pool filter. The pool filter is made from .06 inch stainless steel and was rated for an operating pressure of 50 PSI. As a pool filter, the vessel regularly operated at pressures of 10-15 PSI, and as much as 25-30 PSI when it needed cleaning.

Have run it as a pressure cooker at 3 PSI with no problems. Have run various pressure vessel wall thickness calculators that seem to indicate the vessel could easily handle 15 PSI at 250F.

https://checalc.com/calc/vesselThick.html

Can someone here help verify the design to operate at 15 PSI as a pressure cooker?

Below are details of the build:

Had a .06 inch stainless steel DE pool filter that was being used as a smoker and to pasteurize bulk substrates. Decided to configure it to also work as a steamer by adding 1500 watt heating element and some valves, gauges, and a temperature controller. Holds 55 gallons and used it on its first run to successfully sterilize 8 gallons of coffee and straw bulk substrate.

Plate from the DE pool filter showing 50 PSI operating pressure as a pool filter.

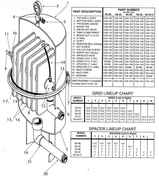

Diagram of pool filter, guts are removed.

1500 watt heater wiring.

Covered and mounted on bottom of barrel.

Inside bottom of barrel with heater installed.

Protective cover and shelf over heater.

PC gauge and pressure weight, and 0-100 PSI pressure control valve.

Temperature controller to turn on and off heater to maintain 2.5 PSI pressure.

Test run with 8 gallons of coffee and straw bulk substrate.

Sterilization at 2.5 PSI in progress.

Sterilization complete, 5 gallon bulk substrate inoculated with Grey oyster mushroom spawn.

8 gallons of sterilized and inoculated bulk substrate.

Changed the temperature controller to one rated for 15 amps, and ran five gallons of straw, coffee grounds and wood pellets bulk substrate. No boom

New 15A temperature controller, off at 212F, on at 210F external temperature.

New bottom rack.

Five gallons straw, coffee, HWFP bulk substrate.

Locked and loaded, time 1617.

Heating up.

At pressure, 2.5 PSI, external temperature 212F, time 1759.

Second DIY steamer experiment at 2.5 PSI complete, start time 1759, end time 2330.

All help appreciated!

Cheers!

Jackal

Have run it as a pressure cooker at 3 PSI with no problems. Have run various pressure vessel wall thickness calculators that seem to indicate the vessel could easily handle 15 PSI at 250F.

https://checalc.com/calc/vesselThick.html

Can someone here help verify the design to operate at 15 PSI as a pressure cooker?

Below are details of the build:

Had a .06 inch stainless steel DE pool filter that was being used as a smoker and to pasteurize bulk substrates. Decided to configure it to also work as a steamer by adding 1500 watt heating element and some valves, gauges, and a temperature controller. Holds 55 gallons and used it on its first run to successfully sterilize 8 gallons of coffee and straw bulk substrate.

Plate from the DE pool filter showing 50 PSI operating pressure as a pool filter.

Diagram of pool filter, guts are removed.

1500 watt heater wiring.

Covered and mounted on bottom of barrel.

Inside bottom of barrel with heater installed.

Protective cover and shelf over heater.

PC gauge and pressure weight, and 0-100 PSI pressure control valve.

Temperature controller to turn on and off heater to maintain 2.5 PSI pressure.

Test run with 8 gallons of coffee and straw bulk substrate.

Sterilization at 2.5 PSI in progress.

Sterilization complete, 5 gallon bulk substrate inoculated with Grey oyster mushroom spawn.

8 gallons of sterilized and inoculated bulk substrate.

Changed the temperature controller to one rated for 15 amps, and ran five gallons of straw, coffee grounds and wood pellets bulk substrate. No boom

New 15A temperature controller, off at 212F, on at 210F external temperature.

New bottom rack.

Five gallons straw, coffee, HWFP bulk substrate.

Locked and loaded, time 1617.

Heating up.

At pressure, 2.5 PSI, external temperature 212F, time 1759.

Second DIY steamer experiment at 2.5 PSI complete, start time 1759, end time 2330.

All help appreciated!

Cheers!

Jackal

Attachments

-

533128410-thumb_FB_IMG_1515331242393.jpg3 KB · Views: 452

533128410-thumb_FB_IMG_1515331242393.jpg3 KB · Views: 452 -

415040271-thumb_anthony-apollo-filter.jpg4.9 KB · Views: 494

415040271-thumb_anthony-apollo-filter.jpg4.9 KB · Views: 494 -

415052643-thumb_20171222_211913.jpg3.3 KB · Views: 430

415052643-thumb_20171222_211913.jpg3.3 KB · Views: 430 -

415062463-thumb_20171222_220142.jpg2.6 KB · Views: 422

415062463-thumb_20171222_220142.jpg2.6 KB · Views: 422 -

415071019-thumb_20171222_221104.jpg2 KB · Views: 410

415071019-thumb_20171222_221104.jpg2 KB · Views: 410 -

415084210-thumb_20171224_145717.jpg3.6 KB · Views: 429

415084210-thumb_20171224_145717.jpg3.6 KB · Views: 429 -

415096476-thumb_20171223_161842.jpg4.2 KB · Views: 419

415096476-thumb_20171223_161842.jpg4.2 KB · Views: 419 -

415117301-thumb_20171223_202334.jpg3.8 KB · Views: 404

415117301-thumb_20171223_202334.jpg3.8 KB · Views: 404 -

415131373-thumb_20171223_154857.jpg3.5 KB · Views: 431

415131373-thumb_20171223_154857.jpg3.5 KB · Views: 431 -

415143829-thumb_20171223_202913.jpg3.9 KB · Views: 406

415143829-thumb_20171223_202913.jpg3.9 KB · Views: 406 -

415156257-thumb_20171224_135910_001.jpg4.4 KB · Views: 430

415156257-thumb_20171224_135910_001.jpg4.4 KB · Views: 430 -

415172154-thumb_20171224_143059.jpg4.8 KB · Views: 415

415172154-thumb_20171224_143059.jpg4.8 KB · Views: 415 -

wink.gif252 bytes · Views: 444

wink.gif252 bytes · Views: 444 -

458121889-thumb_20171228_153208.jpg4 KB · Views: 428

458121889-thumb_20171228_153208.jpg4 KB · Views: 428 -

458138834-thumb_20171228_153618.jpg4.1 KB · Views: 400

458138834-thumb_20171228_153618.jpg4.1 KB · Views: 400 -

458150930-thumb_20171228_160451.jpg3.1 KB · Views: 403

458150930-thumb_20171228_160451.jpg3.1 KB · Views: 403 -

458163637-thumb_20171228_161707.jpg3.6 KB · Views: 443

458163637-thumb_20171228_161707.jpg3.6 KB · Views: 443 -

458176645-thumb_20171228_164142.jpg3 KB · Views: 401

458176645-thumb_20171228_164142.jpg3 KB · Views: 401 -

458204916-thumb_20171228_174736.jpg2.6 KB · Views: 409

458204916-thumb_20171228_174736.jpg2.6 KB · Views: 409 -

458221131-thumb_20171228_232910.jpg3.4 KB · Views: 415

458221131-thumb_20171228_232910.jpg3.4 KB · Views: 415