holdingmyhill

- 2

- 0

Hello,

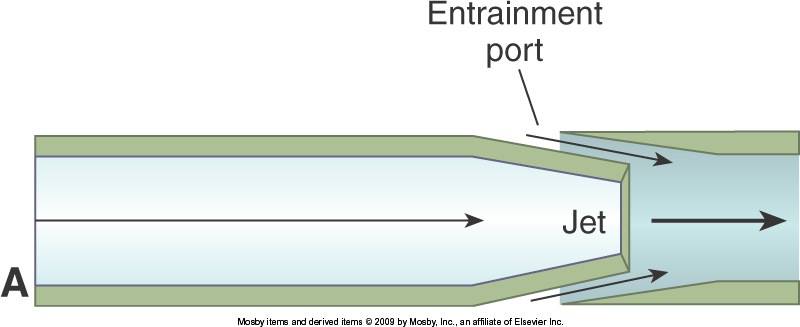

I am trying to analyze an injector and having trouble coming up with the final equation for the calculation. The apparatus can be seen below.

Assuming we know the inlet flow rate and pressure (A) from the pump/fan and the pipe geometry.

The pressure out of the outlet of the nozzle is simple enough:

Pnozzle=Pinlet+1/2*rho*Q^2*(1/Ainlet2-1/Anozzle2)

The suction velocity can be then be calculated based on this pressure.

V=sqrt(2/rho * (Pnozzle-Patm))

However, what I cannot figure out is how to calculate the flow rate of the entrained flow. With this math, the flow is only based on the size of the outer tube.

I am thinking maybe it has to do with shear between the fluid flows? Anybody have any thoughts on this?

I am trying to analyze an injector and having trouble coming up with the final equation for the calculation. The apparatus can be seen below.

Assuming we know the inlet flow rate and pressure (A) from the pump/fan and the pipe geometry.

The pressure out of the outlet of the nozzle is simple enough:

Pnozzle=Pinlet+1/2*rho*Q^2*(1/Ainlet2-1/Anozzle2)

The suction velocity can be then be calculated based on this pressure.

V=sqrt(2/rho * (Pnozzle-Patm))

However, what I cannot figure out is how to calculate the flow rate of the entrained flow. With this math, the flow is only based on the size of the outer tube.

I am thinking maybe it has to do with shear between the fluid flows? Anybody have any thoughts on this?