ham_revilo

- 5

- 0

Hi,

Im currently designing a small machine which uses a simple crank mechanism but my crank mechanism is not a typical one. My application:

[/URL]

[/URL]

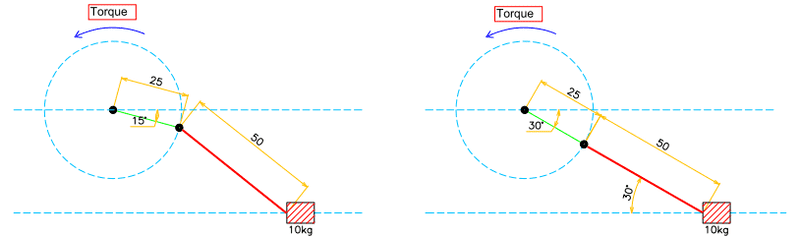

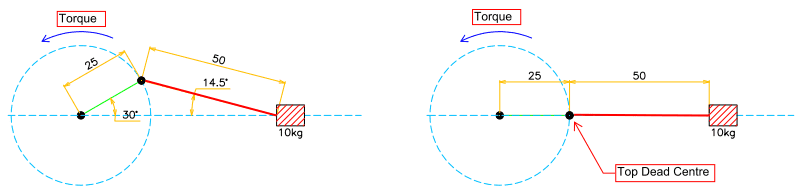

My application uses the crank wheel to drive the block (10kg). Hence, I need to calculate the torque require to drive the crank wheel. So I can select a suitable motor to do so.

The problem is my crank wheel and block is offset. Hence, it’s different from a typical crank mechanism where it’s all in a straight line.

Therefore, my question is:

1. In my application, is there a top/bottom dead centre where torque is 0Nm since its offset?

2. If my case doesn’t have a top/bottom dead centre, how would I calculate the torque required?

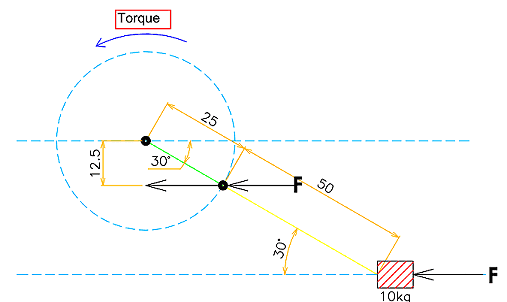

3. I came out with a theory where the Torque=F*12.5. Is it correct?

[/URL]

[/URL]

4. If I’m wrong, Can I use the normal crank mechanism formula (Torque=F*r*sin α) to calculate the torque required?

5. How is the force reaction like so I can resolve it and calculate the torque?

Thanks in advance :)

Im currently designing a small machine which uses a simple crank mechanism but my crank mechanism is not a typical one. My application:

My application uses the crank wheel to drive the block (10kg). Hence, I need to calculate the torque require to drive the crank wheel. So I can select a suitable motor to do so.

The problem is my crank wheel and block is offset. Hence, it’s different from a typical crank mechanism where it’s all in a straight line.

Therefore, my question is:

1. In my application, is there a top/bottom dead centre where torque is 0Nm since its offset?

2. If my case doesn’t have a top/bottom dead centre, how would I calculate the torque required?

3. I came out with a theory where the Torque=F*12.5. Is it correct?

4. If I’m wrong, Can I use the normal crank mechanism formula (Torque=F*r*sin α) to calculate the torque required?

5. How is the force reaction like so I can resolve it and calculate the torque?

Thanks in advance :)

Attachments

Last edited: