BowtoEd

- 1

- 0

I burned out my scavenged motor today and now I think I want to apply a little more thought to moving the project forward.

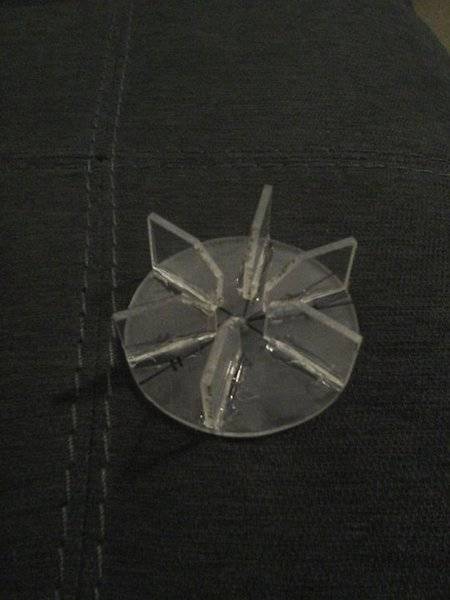

I'm working on a centrifugal blower that can suck air through a charcoal filter so I can keep the air clean around my soldering area. I chose a tuna can for the housing although my impeller (pictured) barely fits. I think I will need a larger housing.

The motor I was using came from a hair dryer. I don't know the ratings but it seemed well behaved at 13.8v, drawing 65 mA when things settled down. The shaft was roughly the same size as my 5/64" drill bit, so I used that to drill the hole. The rotor wasn't perfectly true but it was close.

Anyway, I glued the blades to my impeller and mounted it on the motor with some hot glue. I let it sit for 15 minutes or so for peace of mind that the glue solidified. Then I fired it up. Fire is correct...the impeller ran and I was impressed with the amount of air it pushed amazed me. Then I noticed smoke coming from the motor body. Then the fire came. I killed power, watched the tiny flames die, and then pulled the housing apart to attempt to let the parts cool.

I was more amazed that, an hour later, the motor still turned when I reassembled it. It ran slower and I could see blue sparks issuing from the area where the commutator is. Being a cautious sorceror, I threw the motor in the trash. Maybe I could've salvaged the wire for an RFC or something.

Anyway, I'm hoping to buy a new motor to replace the failed one. I'm looking for ideas for what kind of motor to buy. I see lots of options for RPM. Somehow I don't think that rotating at 15K RPM is going to work. Maybe I should look in the 1000-2000 range. I'm asking here because I think someone else has been down this road before and I'm going to try to find him/her.

Another option is to build a smaller impeller with lighter material and more clearance between the edges of the tuna can. I like this impeller's strength and air movement but I'm not married to it.

Ed

I'm working on a centrifugal blower that can suck air through a charcoal filter so I can keep the air clean around my soldering area. I chose a tuna can for the housing although my impeller (pictured) barely fits. I think I will need a larger housing.

The motor I was using came from a hair dryer. I don't know the ratings but it seemed well behaved at 13.8v, drawing 65 mA when things settled down. The shaft was roughly the same size as my 5/64" drill bit, so I used that to drill the hole. The rotor wasn't perfectly true but it was close.

Anyway, I glued the blades to my impeller and mounted it on the motor with some hot glue. I let it sit for 15 minutes or so for peace of mind that the glue solidified. Then I fired it up. Fire is correct...the impeller ran and I was impressed with the amount of air it pushed amazed me. Then I noticed smoke coming from the motor body. Then the fire came. I killed power, watched the tiny flames die, and then pulled the housing apart to attempt to let the parts cool.

I was more amazed that, an hour later, the motor still turned when I reassembled it. It ran slower and I could see blue sparks issuing from the area where the commutator is. Being a cautious sorceror, I threw the motor in the trash. Maybe I could've salvaged the wire for an RFC or something.

Anyway, I'm hoping to buy a new motor to replace the failed one. I'm looking for ideas for what kind of motor to buy. I see lots of options for RPM. Somehow I don't think that rotating at 15K RPM is going to work. Maybe I should look in the 1000-2000 range. I'm asking here because I think someone else has been down this road before and I'm going to try to find him/her.

Another option is to build a smaller impeller with lighter material and more clearance between the edges of the tuna can. I like this impeller's strength and air movement but I'm not married to it.

Ed