Jimbo86

- 9

- 0

Hi,

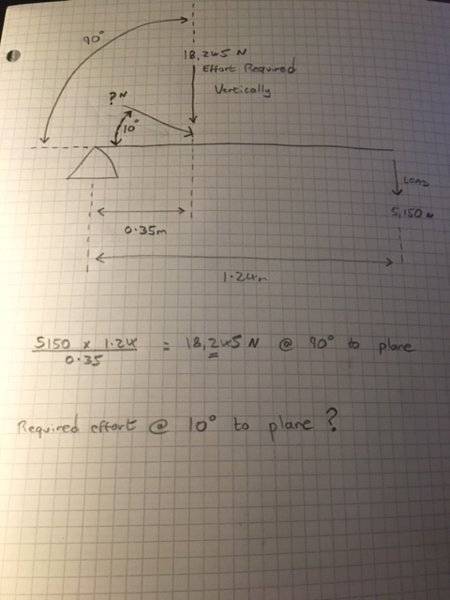

We have a machine in our workshop in which we are modifying to relieve the amount of lifting force required by the hydraulic ram. This will subsequently reduce hydraulic system pressure which is the main goal. I'm trying to calculate the current configuration. It consists of a class 3 lever, with the effort applied at a 30 degree angle to the horizontal plane.

I've tried the following equation:

5150 * 1.24 * sin(10) / 0.35 = 3168N

I know the above is incorrect. At sin(90) perpendicular effort I need 18,245 N to lift the load. I would expect an answer of 3 to 4 times this with the effort applied at 10 degrees.

Please can someone point me in the right direction.

Many thanks

We have a machine in our workshop in which we are modifying to relieve the amount of lifting force required by the hydraulic ram. This will subsequently reduce hydraulic system pressure which is the main goal. I'm trying to calculate the current configuration. It consists of a class 3 lever, with the effort applied at a 30 degree angle to the horizontal plane.

I've tried the following equation:

5150 * 1.24 * sin(10) / 0.35 = 3168N

I know the above is incorrect. At sin(90) perpendicular effort I need 18,245 N to lift the load. I would expect an answer of 3 to 4 times this with the effort applied at 10 degrees.

Please can someone point me in the right direction.

Many thanks