carb

- 9

- 0

Hello,

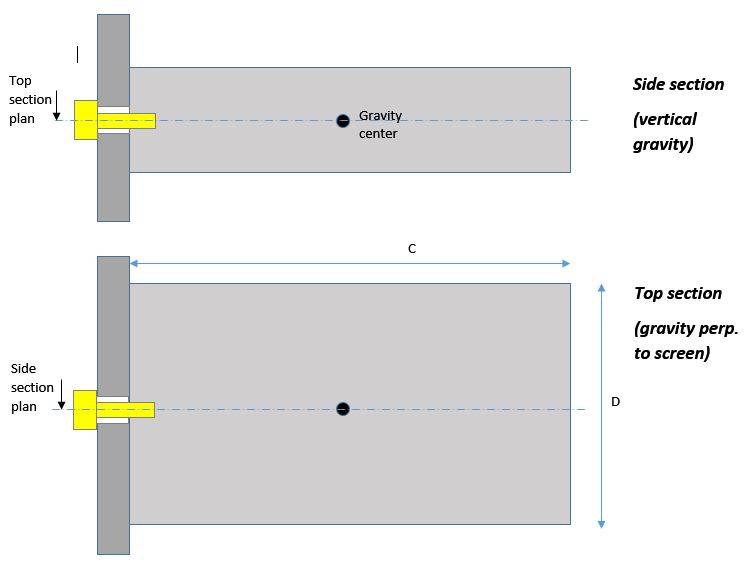

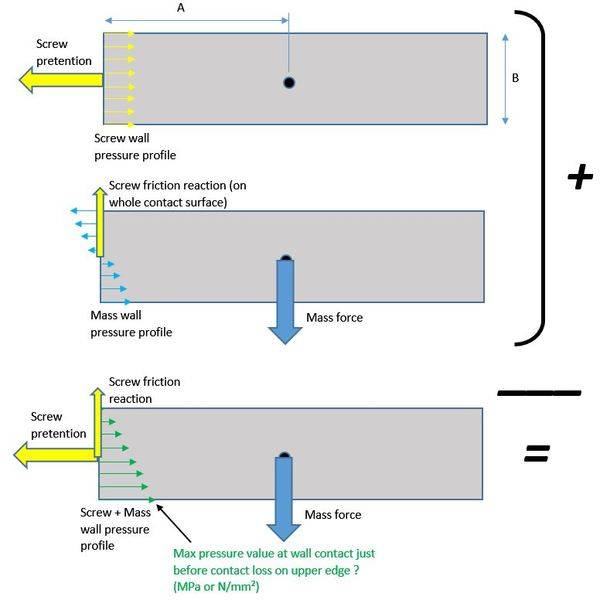

I'd like to calculate the max contact pressure in the below assembly, just before contact loss between the beam and the wall. The beam is clamped to the wall with a pretensioned screw, and sustaining a force at his gravity center.

I'm assuming all bodies dimensionnaly stable (no distorsion).

I wonder about few questions... how to calculate the maximum force at center of gravity before contact loss ? how to work out the composed pressure profile...

Here are some sketches that may help understanding the problem :

Thanks a lot for any kind of help (calculation steps...) !

I'd like to calculate the max contact pressure in the below assembly, just before contact loss between the beam and the wall. The beam is clamped to the wall with a pretensioned screw, and sustaining a force at his gravity center.

I'm assuming all bodies dimensionnaly stable (no distorsion).

I wonder about few questions... how to calculate the maximum force at center of gravity before contact loss ? how to work out the composed pressure profile...

Here are some sketches that may help understanding the problem :

Thanks a lot for any kind of help (calculation steps...) !