- #1

zoobyshoe

- 6,510

- 1,290

So, a few days ago I was beetling down the road, and out of nowhere, the engine started all kinds of unacceptable tomfoolery: spluttering, loss of power, misfiring, hesitation, refusal to accelerate. I pulled over and fiddled with various things for an hour or so, and ended up with it running fine again.

Couple days later, same thing again. I checked vacuum lines and the needle valve especially. After a while, I started it up, and it was fine. Later, though, on the return trip, all the problems returned: sort of a mixture of what it's like when you're running out of gas and only running on 3 cylinders. Luckily, it was down hill all the way home, and I got it back home despite the ailment. But a new symptom cropped up: on top of the other stuff, it backfired a couple times.

I got out my manuals and fired up the Samba archives, and the internet in general, and read for a few hours. Basically, everything said this could either be a fuel system or electrical problem. My points, condenser, wires, and plugs are all less than two months old, so I attacked the carb: pulled it off and sprayed out every orifice and jet 20 times. Then I put it back together, but when I tried to start the car, all I got was a big backfire.

More reading. I ran into reports that brand new, but poor quality, condensers sometimes fail after a very short time. On the remote off chance I might have bought the worst brand new condenser ever, I took it out and put the old one back in.

She started right up, and 30 miles later with no return of the problem, I think that was probably it: the new condenser.

I performed an autopsy on the brand new Autozone Duralast condenser that seems to have failed and found some damning badness inside. Here is some photographic documentation of the procedure:

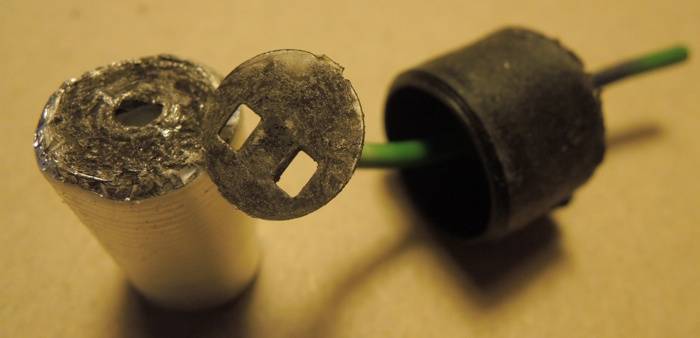

I cut the rolled over "lip" off the can off with a hacksaw. That's the ring around the green wire. Once that's off, I pulled out the rubber plug which insulates one end of the condenser. That's the black thing the green wire goes into.

Pull the rubber plug all the way out, and out drops a little silver "soup can" looking type thing. That is the condenser plates, all rolled up. Notice they are not soldered to anything, or even mechanically connected in any way.

Here is a shot of the inside of the can and one end of the condenser plates. They are clean and shiny: no problems here.

Here is the other end of the plates and the steel contact that is what is on the inside end of the green wire. These don't look so good.

Close up of above elements. You can see this is where the condenser fried. There has been a lot of high voltage sparking between these two things.

This is how the steel contact plate is attached to the green wire.

Starting to unroll the condenser plates. The plates are, as far as I can tell, common aluminum foil. I miked one and it is about .0003 thick. The clear plastic insulation between the foil is about .0005 thick. There are two layers of foil and two layers of plastic. The two layers of foil are offset from each other: one sticks out about 1mm on one side, the other about 1mm on the other side. Once they are rolled up, the excess that is offset is just crushed to the bottom on the can on one end of the roll, and to the steel contact on the other end of the roll.

Here's all the intestines unrolled. I didn't find any evidence of sparking or burning inside; no insulation breakdown between the plates.

The aluminum foil (one plate or layer) is about .670 wide and about 137 inches long. That's an area of 91.79 square inches. It would be a square measuring only about 9.5 inches on a side (though it seems like it'd be larger than that from the pile you see.)

So, what this autopsy reveals is that this is very old, uncomplicated technology. The basic design of these condensers prolly hasn't changed since the 1930's when the car was first designed. Now they use plastic to separate the plates. Back then they used wax paper. It ain't no kind a fancy.

Why did it fail? I don't know. Maybe it was just manufacturing procedure: the rubber insulator wasn't pressed in far enough, leaving a poor contact between the steel and aluminum, inviting a spark to jump and burn the metal. That's plausible, but really just speculation.

Anyway, this is what is going on inside an Autozone Duralast condenser. On Beetle forums I found reports of other makes of condenser failing prematurely, even Bosch, which is alleged to be the highest quality. On top of that, I happened upon an HVAC tech forum thread where a tech was complaining that more and more of the service calls he makes end up being caused by a failed capacitor. Another tech chimed in in agreement and said he was no longer confident about the caps that were traditionally known to be high quality, and didn't know what to tell his customers who were wondering why the caps kept failing.

Is it your experience capacitors are being more and more poorly made?

Couple days later, same thing again. I checked vacuum lines and the needle valve especially. After a while, I started it up, and it was fine. Later, though, on the return trip, all the problems returned: sort of a mixture of what it's like when you're running out of gas and only running on 3 cylinders. Luckily, it was down hill all the way home, and I got it back home despite the ailment. But a new symptom cropped up: on top of the other stuff, it backfired a couple times.

I got out my manuals and fired up the Samba archives, and the internet in general, and read for a few hours. Basically, everything said this could either be a fuel system or electrical problem. My points, condenser, wires, and plugs are all less than two months old, so I attacked the carb: pulled it off and sprayed out every orifice and jet 20 times. Then I put it back together, but when I tried to start the car, all I got was a big backfire.

More reading. I ran into reports that brand new, but poor quality, condensers sometimes fail after a very short time. On the remote off chance I might have bought the worst brand new condenser ever, I took it out and put the old one back in.

She started right up, and 30 miles later with no return of the problem, I think that was probably it: the new condenser.

I performed an autopsy on the brand new Autozone Duralast condenser that seems to have failed and found some damning badness inside. Here is some photographic documentation of the procedure:

I cut the rolled over "lip" off the can off with a hacksaw. That's the ring around the green wire. Once that's off, I pulled out the rubber plug which insulates one end of the condenser. That's the black thing the green wire goes into.

Pull the rubber plug all the way out, and out drops a little silver "soup can" looking type thing. That is the condenser plates, all rolled up. Notice they are not soldered to anything, or even mechanically connected in any way.

Here is a shot of the inside of the can and one end of the condenser plates. They are clean and shiny: no problems here.

Here is the other end of the plates and the steel contact that is what is on the inside end of the green wire. These don't look so good.

Close up of above elements. You can see this is where the condenser fried. There has been a lot of high voltage sparking between these two things.

This is how the steel contact plate is attached to the green wire.

Starting to unroll the condenser plates. The plates are, as far as I can tell, common aluminum foil. I miked one and it is about .0003 thick. The clear plastic insulation between the foil is about .0005 thick. There are two layers of foil and two layers of plastic. The two layers of foil are offset from each other: one sticks out about 1mm on one side, the other about 1mm on the other side. Once they are rolled up, the excess that is offset is just crushed to the bottom on the can on one end of the roll, and to the steel contact on the other end of the roll.

Here's all the intestines unrolled. I didn't find any evidence of sparking or burning inside; no insulation breakdown between the plates.

The aluminum foil (one plate or layer) is about .670 wide and about 137 inches long. That's an area of 91.79 square inches. It would be a square measuring only about 9.5 inches on a side (though it seems like it'd be larger than that from the pile you see.)

So, what this autopsy reveals is that this is very old, uncomplicated technology. The basic design of these condensers prolly hasn't changed since the 1930's when the car was first designed. Now they use plastic to separate the plates. Back then they used wax paper. It ain't no kind a fancy.

Why did it fail? I don't know. Maybe it was just manufacturing procedure: the rubber insulator wasn't pressed in far enough, leaving a poor contact between the steel and aluminum, inviting a spark to jump and burn the metal. That's plausible, but really just speculation.

Anyway, this is what is going on inside an Autozone Duralast condenser. On Beetle forums I found reports of other makes of condenser failing prematurely, even Bosch, which is alleged to be the highest quality. On top of that, I happened upon an HVAC tech forum thread where a tech was complaining that more and more of the service calls he makes end up being caused by a failed capacitor. Another tech chimed in in agreement and said he was no longer confident about the caps that were traditionally known to be high quality, and didn't know what to tell his customers who were wondering why the caps kept failing.

Is it your experience capacitors are being more and more poorly made?