Saladsamurai

- 3,009

- 7

!Shear Diagram!

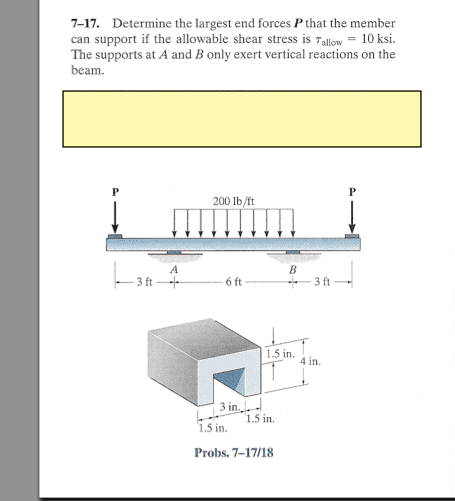

I have posted the problem below. I am looking to find P max. My professor wants us to draw a shear diagram to find out where it will occur.

From equilibrium equations I have found that Ay=By=P+0.6 kip

I am having trouble drawing the diagram. I know it starts with -P and is constant until it hits Ay. Then I add -P+(P+.6) So it is +.6

Now there is a distributed load. So it should decrease linearly. But that is where I am stuck. Where does it decrease to? Does it cross the x-axis at all? Sorry, but I just can't see this one straight...

Homework Statement

I have posted the problem below. I am looking to find P max. My professor wants us to draw a shear diagram to find out where it will occur.

From equilibrium equations I have found that Ay=By=P+0.6 kip

I am having trouble drawing the diagram. I know it starts with -P and is constant until it hits Ay. Then I add -P+(P+.6) So it is +.6

Now there is a distributed load. So it should decrease linearly. But that is where I am stuck. Where does it decrease to? Does it cross the x-axis at all? Sorry, but I just can't see this one straight...