calvinyeh

- 3

- 0

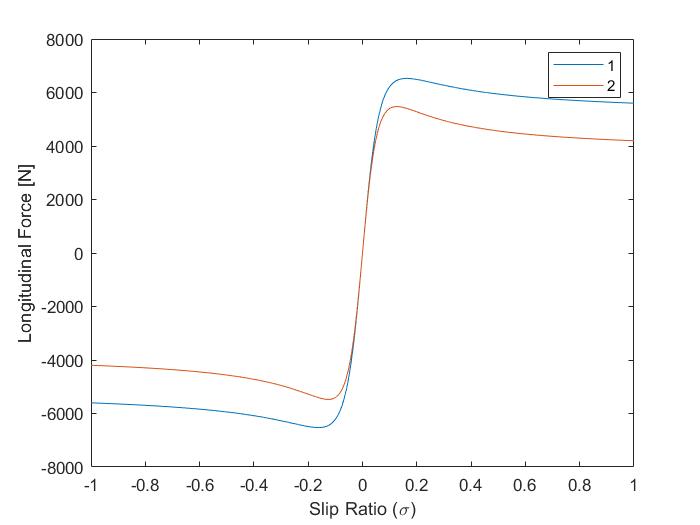

The graph is relationship between longitudinal force and slip ratio under the conditions of 0 longitudinal acceleration and flat road(0 angle of inclination). Which line represent FWD or RWD? Does FWD or RWD have higher maximum slip ratio?