Joe591

- 56

- 34

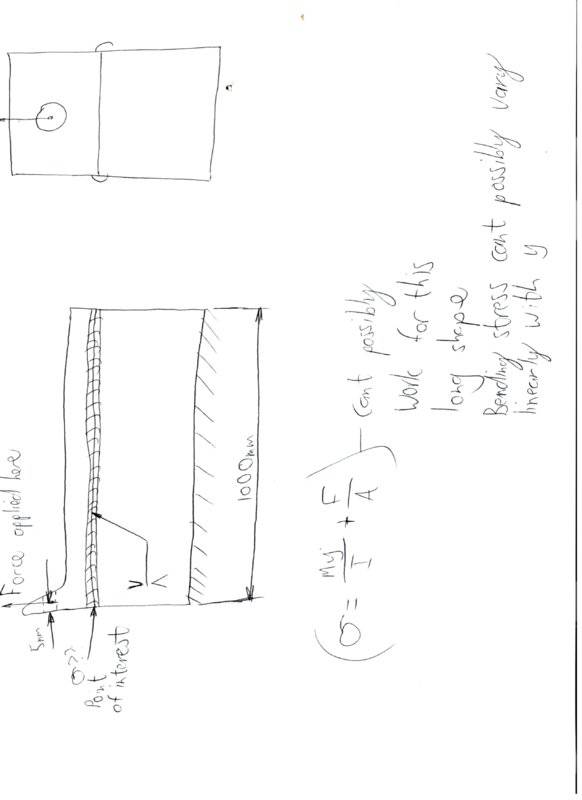

I've attached a photo of a "problem". How would you calculate the stress at the area in question? I seriously doubt that the bending stress would vary linearly throughout the whole meter of total length of the section. I would expect it to become zero long before it reaches the opposite extremity. Please point me in the direction of an applicable text. An online source would be nice... Really hope the picture is clear...