jnnx

- 28

- 1

hi guys

did you noticed announcement of new koenigsegg regera?

http://jalopnik.com/how-the-1-500-hp-koenigsegg-regera-hits-248-mph-without-1689181377

1500hp, two electric motors driving wheels, and one connected to engine. no transmission, only hydraulic clutch and final drive.

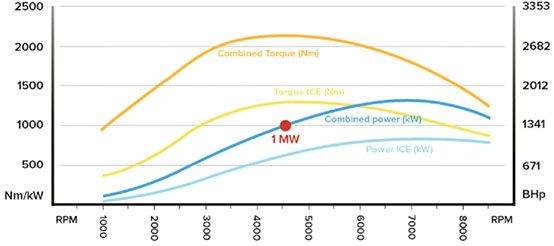

interesting thing is, that they said the engine engages at ~50kmh, and at lower speeds, electricity is moving the vehicle. they also published a graph of power and torque figures of whole propulsion system. 0-60mph at 2.8sec, 0-250mph at sub 20 seconds.

my problem is this. if you look at the combined torque figure ( at 1000rpm) there is around 600Nm of electric torque. we can assume, that that is torque of two electric motors. there is final drive (2.85:1) between engine and motors, so that two motors would produce aprox (600nm*2.85) 1710Nm going to the wheels. and that is actually very very little. 2l petrol engine with transmission (lets say 4:1 for first gear and 4:1 final drive) sending to the wheels like (200nm*4*4) 3200Nm

I put it all (weight, aprox torque curve, gear, tyres, aero coefficient...) in my excel sheet which can calculate thinks like this and with this torque, it calculated that 0-50kmh would take almost 5 seconds and 0-100kmh something like 7seconds that is more than twice more than official time. other acceleration figures (90-150mph and 30-250mph) it calculated very close to official figures.

so help me here. did I make somewhere a mistake? because unless the published power/torque curves are wrong, I can't understand how it could achieve that 0-60mph acceleration time.

did you noticed announcement of new koenigsegg regera?

http://jalopnik.com/how-the-1-500-hp-koenigsegg-regera-hits-248-mph-without-1689181377

1500hp, two electric motors driving wheels, and one connected to engine. no transmission, only hydraulic clutch and final drive.

interesting thing is, that they said the engine engages at ~50kmh, and at lower speeds, electricity is moving the vehicle. they also published a graph of power and torque figures of whole propulsion system. 0-60mph at 2.8sec, 0-250mph at sub 20 seconds.

my problem is this. if you look at the combined torque figure ( at 1000rpm) there is around 600Nm of electric torque. we can assume, that that is torque of two electric motors. there is final drive (2.85:1) between engine and motors, so that two motors would produce aprox (600nm*2.85) 1710Nm going to the wheels. and that is actually very very little. 2l petrol engine with transmission (lets say 4:1 for first gear and 4:1 final drive) sending to the wheels like (200nm*4*4) 3200Nm

I put it all (weight, aprox torque curve, gear, tyres, aero coefficient...) in my excel sheet which can calculate thinks like this and with this torque, it calculated that 0-50kmh would take almost 5 seconds and 0-100kmh something like 7seconds that is more than twice more than official time. other acceleration figures (90-150mph and 30-250mph) it calculated very close to official figures.

so help me here. did I make somewhere a mistake? because unless the published power/torque curves are wrong, I can't understand how it could achieve that 0-60mph acceleration time.