Discussion Overview

The discussion revolves around modeling two-phase flow of air through a packed bed, with a focus on incorporating the freezing of CO2 from the process stream. Participants explore various models and approaches, discussing the complexities of thermodynamics and phase behavior in the context of this system.

Discussion Character

- Exploratory

- Technical explanation

- Debate/contested

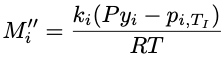

- Mathematical reasoning

Main Points Raised

- Some participants propose that the CO2 will not move through the bed as a solid plug but may deposit temporarily on the bed.

- Others suggest that if the bed is colder than the freezing point of CO2, the CO2 in the stream could freeze upon entering the bed, potentially leading to a 'plug' formation at the outlet.

- A participant mentions the need to understand the thermodynamics of the three-component mixture (O2, N2, CO2) before proceeding with the modeling.

- There are discussions about the vapor pressure vs temperature of the components and the importance of phase equilibrium calculations for the two-phase and possibly three-phase regions.

- One participant expresses uncertainty about the timing of the freezing and vaporization processes of CO2, suggesting that it may affect the distribution of frozen CO2 along the bed.

- Another participant plans to create plots for pressure vs saturation temperature, vapor fraction vs temperature and pressure, and phase composition vs temperature and pressure to aid in understanding the system.

- Concerns are raised about the operational pressure needed to allow for desublimation of CO2, noting that it must be below the triple point pressure of CO2.

Areas of Agreement / Disagreement

Participants express differing views on the behavior of CO2 in the packed bed, particularly regarding its phase transitions and movement. There is no consensus on the best approach to modeling the system or the implications of the thermodynamic properties discussed.

Contextual Notes

Participants highlight the need for a thorough understanding of thermodynamic principles and phase behavior before advancing to more complex modeling, indicating that assumptions about the behavior of CO2 may affect the outcomes of the models.