casualguitar

- 503

- 26

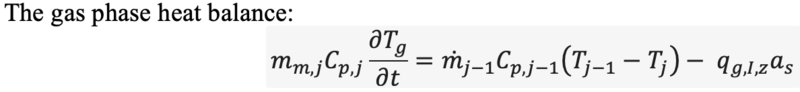

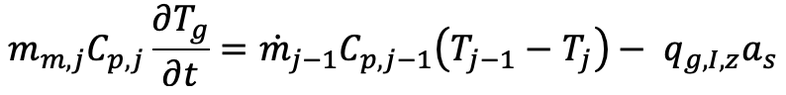

Agreed that this is unrelated to composition. However we mentioned earlier that we're not tracking composition changes in the gas phase so would this exiting molar flow technically be of the same composition as the inlet flow. Yes we will lose some of each component to the solid phase, however is it correct to say we assume that this does not affect the gas phase composition?Chestermiller said:This has nothing to do with composition. It says that the total number of moles exiting the tank per unit time is equal to the total number of moles per unit time entering minus the rate of change in the number of moles as a result of the rate of temperature increase at constant pressure, and minus the molar rates of solid- and liquid deposition onto the bed.

So we have 6 ODEs here, and 2 ODEs in the last model, would that be 3 times the number of ODEs being solved? Or am I missing something? But yes it does seem like this could add significantly to the computation time. That said, we don't need thermo to calculate T(H,P) or the density/enthalpy derivative. I think these were quite costly so hopefully this balances out somewhat.Chestermiller said:You realize that there are 6 times the number of tanks number of coupled ODEs being solved, right? This involves the solution of 6 times the number of tanks non-linear algebraic equations being solved at each time step.

Agreed yes I think constant U, mass transfer coefficient and even constant Cp just to see how the code for this will look. Will start coding on this system tomorrow morning!Chestermiller said:I guess you can start out by assuming constant values for the heat transfer coefficients and mass transfer coefficients. The actual coding for these could be added later within the derivative determination subroutine.