Screw elongation has consequences, but these are difficult to evaluate, as this elongation must be absorbed by the elastic deformation of the thread. I suppose a finer thread is less able to spread the force over the nut height. With the usual coarse thread, books consider it's not a worry if the steel nut height equals the screw diameter. But if you overstress an assembly, you can see the first turns bent more than the last ones.

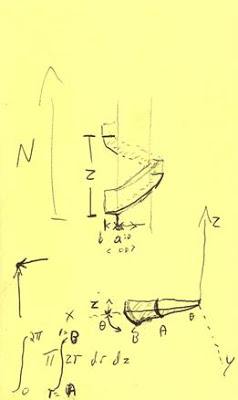

One might perhaps - ho knows - maybe - bizarre idea - mismatch the screw's pitch at rest (0.3% at 700MPa!), so it matches the nut at normal stress. But I'd prefer to make the nut's cross-area as big as the screw and hold the nut at its top if the screw is loaded at its bottom, so both deform by the same amount. The screw and the nut should even be tapered, with little area at the unloaded end. Even spread of load then, no length limit, fun.

Edit: your screw will be used at varied positions, so you can't optimize its tapering, pity. But you can taper the nut and load it at its top.

I hadn't got properly your explanation, so my reply is largely off. In case you want to increase the fillet radius to reduce stress concentration and accept for that purpose to reduce the contact area and increase the contact pressure or the screw's size:

The analysis with contact pressure ans stress concentration has already been done and optimized at standard profiles ( which include profiles tilted so the pressure surface is perpendicular to the axis, thus minimizing the expanding force at the nut as well as the tightening torque - your choice if I understand properly). And because they're already optimized, I'd stick to standard profiles. Be careful that most FEM software fails to compute stress concentration at contacts.

Also, most contacting parts, especially screws, work with loads exceeding locally the elastic limit, and work well because the material accepts it, and because the plastic deformation occurs only once to accommodate the matching parts. This is very difficult to predict, and isn't acceptable if the load varies many times - this lost some aeroplanes and let airframe designers try to prevent it with very specific methods.

To evaluate the contact area, I really believe you need only to project it perpendicularly to the desired force. That is, if pressure P works perpendicularly (thanks to slip) on the local surface element S that has the angle A with the desired force, the contribution is P*S*cos(A), and in S*cos(A) you recognize the projected area - where the angle A includes all contributions: pitch, fillet angle...

Did you consider a hollow screw? Removing some metal at the centre would lose very little area, and would help a lot to quench the steel. Ask your heat treatment contractor if this suffices to the water flow, but a ID=100mm hole in a OD=300mm cylinder slashes the thickness to 100mm, and then many cheaper steel compositions give you tempered 1000MPa: stronger than 700MPa at full D=300.