SlimJ87D

- 6

- 0

hello everyone, this is my first post.

Right now I am trying to figure out which equations to use to solve the following.

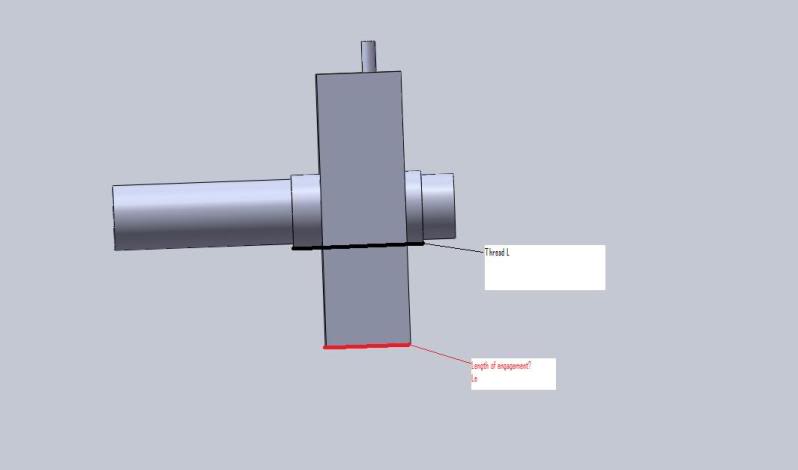

I will have a block that will a threaded rod through it. This block will be next to another larger block. In between these blocks are going to be metal samples.

Now here is the cool part, when I turn the thread via gears and such, the block that is engaged with the threaded rod will move and help deform the separate metal samples till failure occurs.

I need to know how much engagement (Le) the block has to have with the threaded rod so failure will not occur.

Some helpful givens:

-I am using steel

-The amount of force needed to break these samples is approximately 300lbs, that is 150 in the opposite directions of the sample.

Right now I am trying to figure out which equations to use to solve the following.

I will have a block that will a threaded rod through it. This block will be next to another larger block. In between these blocks are going to be metal samples.

Now here is the cool part, when I turn the thread via gears and such, the block that is engaged with the threaded rod will move and help deform the separate metal samples till failure occurs.

I need to know how much engagement (Le) the block has to have with the threaded rod so failure will not occur.

Some helpful givens:

-I am using steel

-The amount of force needed to break these samples is approximately 300lbs, that is 150 in the opposite directions of the sample.