jessemk

- 1

- 0

hello.

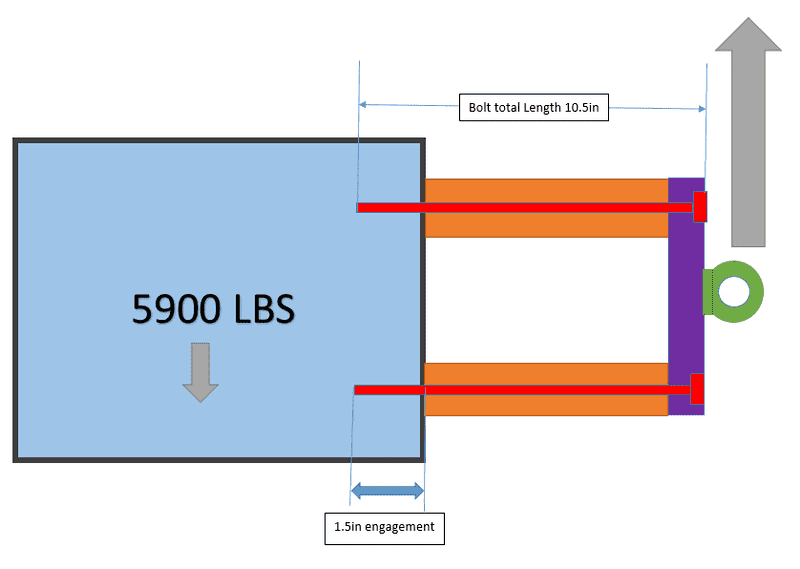

I have a ejection mold (steel) which has a bridge like mount which locates the handling eye bolts outward around hydraulic cylinders. I need to make sure the bolts in the bridge will not shear due to the sideways load when the mold is lifted or flipped 90degrees. Here is the known information:

mold weight: 5,900 lbs

Bolt Dia: 5/8"

Bolt total length: 10.5"

Bolt thread engagement: 1.125"

Number of bolts in bridge 4

Color representation:

blue:Injection mold

orange: cylindrical steel pillars with a clearance hole through

purple: eye bolt mounting plate

Red:Bolt-socket head cap screw

I have a ejection mold (steel) which has a bridge like mount which locates the handling eye bolts outward around hydraulic cylinders. I need to make sure the bolts in the bridge will not shear due to the sideways load when the mold is lifted or flipped 90degrees. Here is the known information:

mold weight: 5,900 lbs

Bolt Dia: 5/8"

Bolt total length: 10.5"

Bolt thread engagement: 1.125"

Number of bolts in bridge 4

Color representation:

blue:Injection mold

orange: cylindrical steel pillars with a clearance hole through

purple: eye bolt mounting plate

Red:Bolt-socket head cap screw