Ulysees

- 515

- 0

This is an attempt to calculate the efficiency of a modern gasoline engine (Volkswagen's 1.6 litre FSI).

The result seems too good to be true. Please let me know if there is any error.

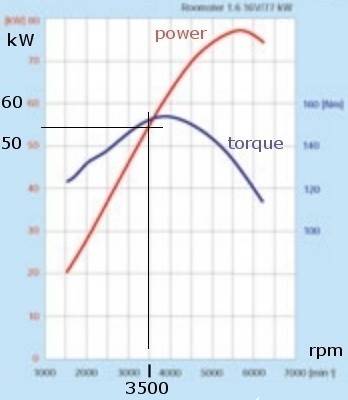

At a constant 100 km/h on a flat motorway, the consumption of my car reads 5.7 l/100 km. The engine revs at exactly 3500 rpm. From the power curve below, the power output at this rpm is 54 kW = 54000 joules per second

The consumption of 5.7 l/100 km at 100 km/h translates into 5.7 litres per hour, or 5.7 / 3600 = 0.00158 litres per second.

Therefore the energy per litre is 54000 joules / 0.00158 litres = 34.2 megajoules per litre

According to wikipedia, "gasoline contains about 34.6 megajoules per litre":

http://en.wikipedia.org/wiki/Gasoline

Therefore the efficiency of my engine is:

efficiency = output energy / input energy = 34.2 / 34.6 = 98.8%

But someone said internal combustion engines have a typical efficiency of 15-20%. Was that about old technology in fact?

Or is the 1.6 FSI so incredibly efficient?

The result seems too good to be true. Please let me know if there is any error.

At a constant 100 km/h on a flat motorway, the consumption of my car reads 5.7 l/100 km. The engine revs at exactly 3500 rpm. From the power curve below, the power output at this rpm is 54 kW = 54000 joules per second

The consumption of 5.7 l/100 km at 100 km/h translates into 5.7 litres per hour, or 5.7 / 3600 = 0.00158 litres per second.

Therefore the energy per litre is 54000 joules / 0.00158 litres = 34.2 megajoules per litre

According to wikipedia, "gasoline contains about 34.6 megajoules per litre":

http://en.wikipedia.org/wiki/Gasoline

Therefore the efficiency of my engine is:

efficiency = output energy / input energy = 34.2 / 34.6 = 98.8%

But someone said internal combustion engines have a typical efficiency of 15-20%. Was that about old technology in fact?

Or is the 1.6 FSI so incredibly efficient?

Last edited: