r4m0n0

- 2

- 0

Hello, this is my first post. This question is related to my final thesis.

I'm calculating the heat exchange area of a radiator through heat exchange equations:

Q = U*A*LMTD

I have as data Q, and LMTD (this one through trivial calculations)

In order to calculate U, I need the coefficients for external and internal (both tubes and fins) convection.

Internal convection coefficient is quite easy to calculate.

My doubts come when trying to calculate the external convection coefficient. As you may know to calculate the coefficient you need the Reynolds number (amongst other things).

Reynolds depends on the fluid speed (in this case air speed) and in order to calculate it I thought of the following equation:

v=(V_dot_air)/(no.of tubes*area of tubes) --->

The thing is... this calculation doesn't take in account the fins of the radiator, thus not having an accurate value for velocity.

But if I took in account the area of the fins into the equation, the velocity of air would be very VERY slow.

Can anyone suggest a better way to calculate air speed through a car radiator?

Thanks in advance :)

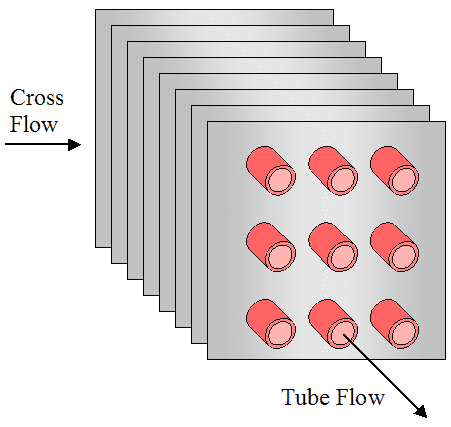

(Image enclosed: a simplification of a car radiator)

I'm calculating the heat exchange area of a radiator through heat exchange equations:

Q = U*A*LMTD

I have as data Q, and LMTD (this one through trivial calculations)

In order to calculate U, I need the coefficients for external and internal (both tubes and fins) convection.

Internal convection coefficient is quite easy to calculate.

My doubts come when trying to calculate the external convection coefficient. As you may know to calculate the coefficient you need the Reynolds number (amongst other things).

Reynolds depends on the fluid speed (in this case air speed) and in order to calculate it I thought of the following equation:

v=(V_dot_air)/(no.of tubes*area of tubes) --->

The thing is... this calculation doesn't take in account the fins of the radiator, thus not having an accurate value for velocity.

But if I took in account the area of the fins into the equation, the velocity of air would be very VERY slow.

Can anyone suggest a better way to calculate air speed through a car radiator?

Thanks in advance :)

(Image enclosed: a simplification of a car radiator)