TheRedDevil18

- 406

- 2

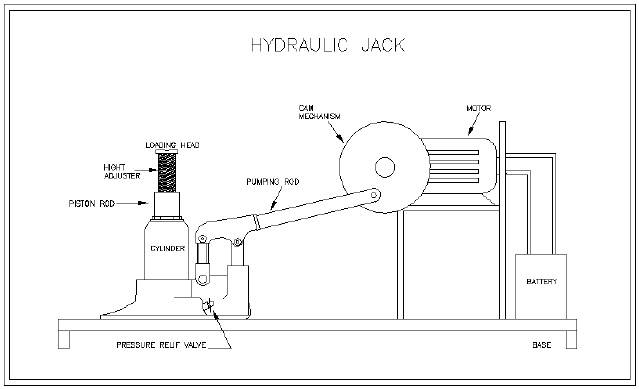

What type of motor can I use for this jack ?

It's running from a 12V battery

It's running from a 12V battery

+1, w/o telescoping handle the jack or motor would need to be on a sliding mechanism. probably bad to have the jack slide back & forth ;)gjonesy said:Unless you have a telescoping arm on the jack that design wouldn't work, and you would have to manually let the jack down. a scissor jack with a reversible electric motor straight shaft input attached to the jack itself would work much better.

.

Baluncore said:Sliding mechanisms are usually quite inefficient unless they have captive linear ball races.

A connecting rod would be a better method of connecting the crank to the jack arm. By selecting appropriate linkage dimensions and motor position, the motor torque could be optimised to the lifting part of the rotation cycle. A simple change to the jack handle socket would allow operation by horizontal motion rather than vertical.

That looks like it would work, so long as the ends of the connecting rod were pins that would allow for the directional differences.TheRedDevil18 said:What if I just changed the connecting rod position to something like this

I expect the pressure "release valve" that is wrongly labelled as “pressure relief” valve will be cracked open slightly.gjonesy said:How are you going to lower the jack?