Engineer_Phil

- 27

- 0

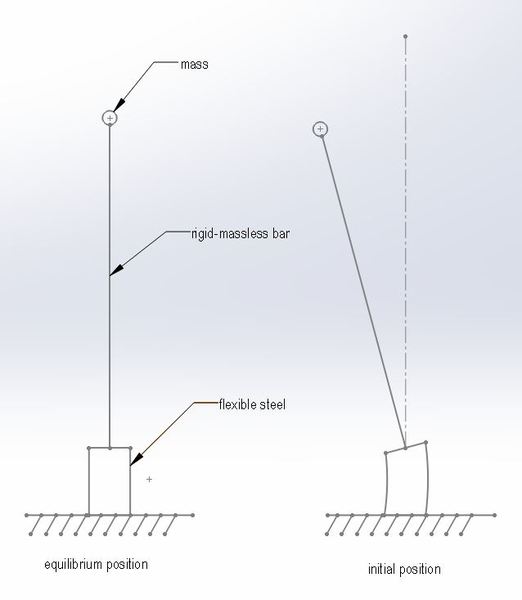

I am trying to estimate the damping ratio of steel in bending. I have a situation where I need to know the dynamic response of an inverted pendulum. A picture is worth a thousand words, so here you go:

The vibration will be free; it is caused be the initial position of the system. I can calculate the stiffness of the flexural steel based on the length, cross section, and material properties.

The problem is estimating the damping. I want to know how long it takes the ocsillations to die down to a specified level.

I have done some research on google and so far I have only been able to find lengthy thesis full of differential equations and no real applicable conclusions. I am aware of the logarithmic decrement method, but I do not have the luxury of setting up a full scale model.

What I am looking for is some sort of relation between the geometry and the material properties to estimate the damping. Can someone point me in the right direction?

Thank you!

The vibration will be free; it is caused be the initial position of the system. I can calculate the stiffness of the flexural steel based on the length, cross section, and material properties.

The problem is estimating the damping. I want to know how long it takes the ocsillations to die down to a specified level.

I have done some research on google and so far I have only been able to find lengthy thesis full of differential equations and no real applicable conclusions. I am aware of the logarithmic decrement method, but I do not have the luxury of setting up a full scale model.

What I am looking for is some sort of relation between the geometry and the material properties to estimate the damping. Can someone point me in the right direction?

Thank you!