gpsimms

- 30

- 1

Ok very much amateur here, appreciate any advice.

So, the guy at home depot suggested the ballast was the reason my flourescent kitchen light goes out occasionally. The light worked well for the first 3 years of ownership. Now, it doesn't buzz or flicker, it just occasionally doesn't work.

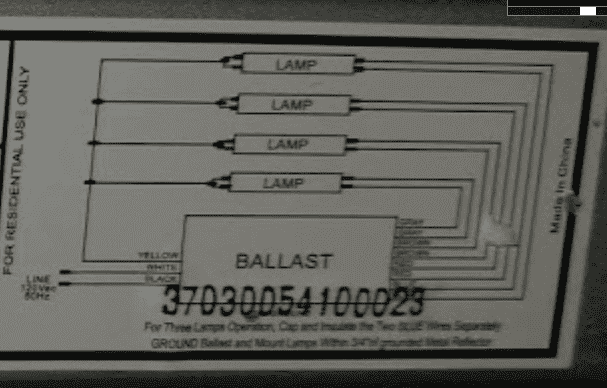

After some time, it will work fine again. Anyway, home depot says change the ballast, here's what you need. Seems simple enough, I remove the old ballast and then realize that the wiring diagrams are different.

Here is the old:

And here is the new:

So basically, on the yellow end of the bulbs, I need to put two bulbs in parallel (instead of all 4). And on red/blue ends, one wire goes to each bulb, and then the two prongs are in parallel instead of a separate wire going to each individual lead.

Here is my question:

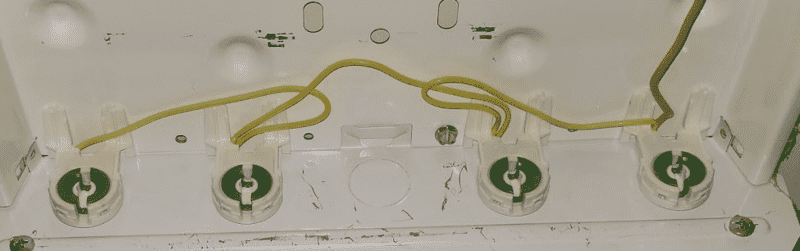

The old yellow end is wired like this:

I'm just wondering if it's ok to wire up one end of the prongs only, as is done here, or if it was previously wired incorrectly, and instead the yellow wires should go to each prong as is shown in the wiring diagram.

Thanks in advance for the patience regarding my dumb question.

So, the guy at home depot suggested the ballast was the reason my flourescent kitchen light goes out occasionally. The light worked well for the first 3 years of ownership. Now, it doesn't buzz or flicker, it just occasionally doesn't work.

After some time, it will work fine again. Anyway, home depot says change the ballast, here's what you need. Seems simple enough, I remove the old ballast and then realize that the wiring diagrams are different.

Here is the old:

And here is the new:

So basically, on the yellow end of the bulbs, I need to put two bulbs in parallel (instead of all 4). And on red/blue ends, one wire goes to each bulb, and then the two prongs are in parallel instead of a separate wire going to each individual lead.

Here is my question:

The old yellow end is wired like this:

I'm just wondering if it's ok to wire up one end of the prongs only, as is done here, or if it was previously wired incorrectly, and instead the yellow wires should go to each prong as is shown in the wiring diagram.

Thanks in advance for the patience regarding my dumb question.