BatsDude

- 14

- 0

Hi guys,

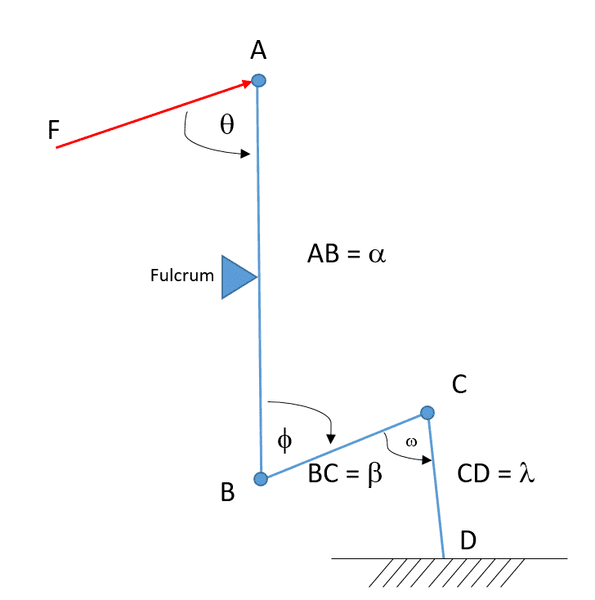

It's been a while since I've done much resolving forces stuff, and I'm struggling to make sure what I'm doing is right. I have a setup like below, and I want to find the torque around point D due to the force acting at point A.

I've had a couple attempts but I feel like I'm just guessing and I'm not sure if I'm correct.

I know the force acting at A produces a torque at the fulcrum of F*(alpha/2)*sin(theta) but is this the force that's also seen in the BC member? From what I understand, if I can find the force acting in the BC member, it should be easy to find the torque around point D.

Any help would be good! Thanks

It's been a while since I've done much resolving forces stuff, and I'm struggling to make sure what I'm doing is right. I have a setup like below, and I want to find the torque around point D due to the force acting at point A.

I've had a couple attempts but I feel like I'm just guessing and I'm not sure if I'm correct.

I know the force acting at A produces a torque at the fulcrum of F*(alpha/2)*sin(theta) but is this the force that's also seen in the BC member? From what I understand, if I can find the force acting in the BC member, it should be easy to find the torque around point D.

Any help would be good! Thanks