j0nr

- 2

- 0

Hello all,

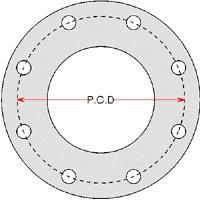

I am trying to remember (I did it in Uni) how to calculate the effective mean radius of an annulus that contains a pattern of holes on a PCD.

Consider the following image (pinched from: https://www.solenoid-valves.com/ ):

If one was to vary the value of PCD, then the effective mean radius would change (I believe). But how do you work out the effective mean radius for purposes of friction torque transmission calcs?

Thanks in advance,

Jon

I am trying to remember (I did it in Uni) how to calculate the effective mean radius of an annulus that contains a pattern of holes on a PCD.

Consider the following image (pinched from: https://www.solenoid-valves.com/ ):

If one was to vary the value of PCD, then the effective mean radius would change (I believe). But how do you work out the effective mean radius for purposes of friction torque transmission calcs?

Thanks in advance,

Jon