DarkBlitz

- 22

- 0

Hello guys,

I am doing some basic design work and can't remember how offset torques work.

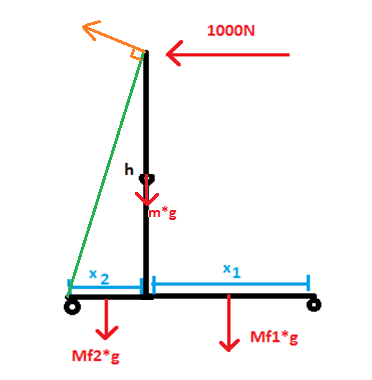

I am doing the sum of the torques should be equal to 0 in order to find the tipping point around either of the wheels.

My problem is with the 1000N applied at to top taking the pivot point around the left wheel.

Should I be using the component of the 1000N which is at right angles to the distance to the pivot point? (the green line) and take the green line as the distance? should I use 'h' as the distance to the pivot point with 1000N as the force? or a combination of both?

The same for m*g in the diagram. Should I assume that the centre of mass is where the weight is applied and take the perpendicular component?

Thanks very much for your help guys! Been a long time since I looked into this.

I am doing some basic design work and can't remember how offset torques work.

I am doing the sum of the torques should be equal to 0 in order to find the tipping point around either of the wheels.

My problem is with the 1000N applied at to top taking the pivot point around the left wheel.

Should I be using the component of the 1000N which is at right angles to the distance to the pivot point? (the green line) and take the green line as the distance? should I use 'h' as the distance to the pivot point with 1000N as the force? or a combination of both?

The same for m*g in the diagram. Should I assume that the centre of mass is where the weight is applied and take the perpendicular component?

Thanks very much for your help guys! Been a long time since I looked into this.