cmih

- 2

- 0

I have what I think is probably a simple problem for someone with the right experience. I happened upon this forum while using Google.

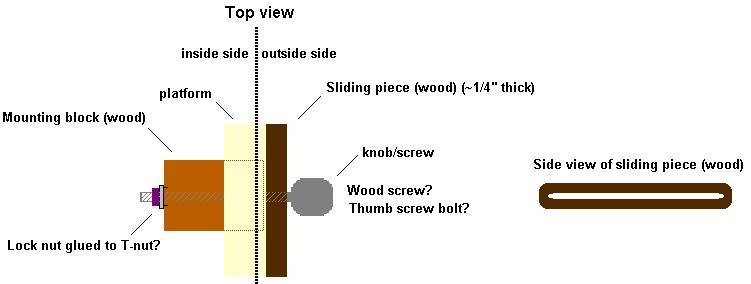

The drawing below (not to scale) shows the basic setup. There is wood mounting block. Adjacent to the mounting block is a 1/4" thick piece of wood with a slot down the middle. The slot will allow the piece to be moved to different positions and angles. Attached to the top of the sliding piece is a platform (yellow).

The idea is to have an adjusting "knob" or screw that I can tighten to hold the slotted wood in position (against the mounting block). I want to be able to loosen the adjusting knob/screw to change the position of the slotted piece, and then tighten the knob/screw to hold the slotted wood in the new position securely.

The challenge is to find a way to make the screw/bolt stay tight until I loosen it. And I do not want to have to access the inside side of the mounting block when I loosen or tighten the screw/bolt.

When I went to the hardware store there were so many different types of screws and bolts and washers and nuts I could not decide on what to get. Below are a couple of different ways I've thought of to do this.

1. Use an eyelet screw (with wood screw type threads) and screw it into the mounting block, but not all the way through the mounting block. I think the friction between the screw and the wood would be sufficient to keep the screw tight. And, if it starts to loosen, I can just screw the screw further into the mounting block.

2. Drill a hole though the mounting block. Then use a thumb screw (with bolt threads) with a T-nut (hammered into the wood) on the inside side of the mounting block, and have a lock nut superglued to the T-nut. As long as I get the lock nut properly aligned with the T-nut and the superglue holds, it should hold the bolt tight.

I think there must be a better solution than what I've thought of so far, but I don't have much experience with putting things together. I would appreciate some advice. Thanks.

The drawing below (not to scale) shows the basic setup. There is wood mounting block. Adjacent to the mounting block is a 1/4" thick piece of wood with a slot down the middle. The slot will allow the piece to be moved to different positions and angles. Attached to the top of the sliding piece is a platform (yellow).

The idea is to have an adjusting "knob" or screw that I can tighten to hold the slotted wood in position (against the mounting block). I want to be able to loosen the adjusting knob/screw to change the position of the slotted piece, and then tighten the knob/screw to hold the slotted wood in the new position securely.

The challenge is to find a way to make the screw/bolt stay tight until I loosen it. And I do not want to have to access the inside side of the mounting block when I loosen or tighten the screw/bolt.

When I went to the hardware store there were so many different types of screws and bolts and washers and nuts I could not decide on what to get. Below are a couple of different ways I've thought of to do this.

1. Use an eyelet screw (with wood screw type threads) and screw it into the mounting block, but not all the way through the mounting block. I think the friction between the screw and the wood would be sufficient to keep the screw tight. And, if it starts to loosen, I can just screw the screw further into the mounting block.

2. Drill a hole though the mounting block. Then use a thumb screw (with bolt threads) with a T-nut (hammered into the wood) on the inside side of the mounting block, and have a lock nut superglued to the T-nut. As long as I get the lock nut properly aligned with the T-nut and the superglue holds, it should hold the bolt tight.

I think there must be a better solution than what I've thought of so far, but I don't have much experience with putting things together. I would appreciate some advice. Thanks.