harrelltim

- 3

- 0

Hi I am a student trying to figure out how to work ANSYS. The load case never seem to work would appreciate any help. Here is my problem.

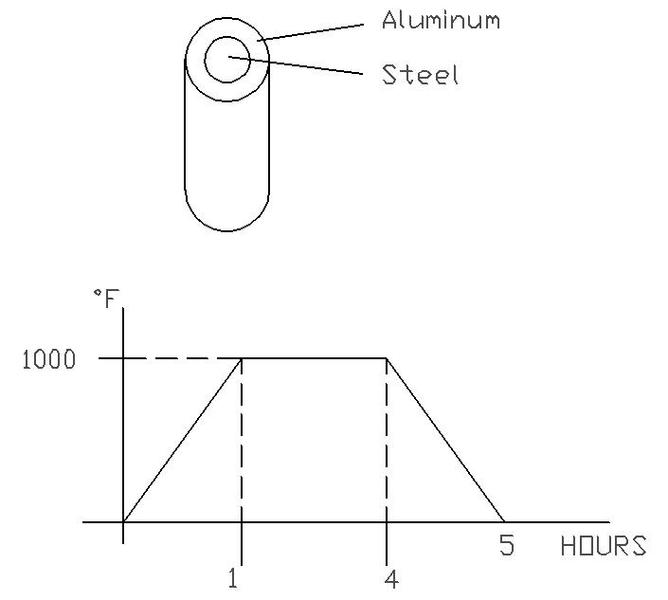

Two cylinder materials, as shown. The dimensions don't really matter all too much. I then want to have the initial temp at 0 then ramped to 1000 and constant for 3 hours and then back down to zero.

Also, if you know then how to run that same analysis over 800 cycles would be great.

Anything will help. I believe that it is going to be a transient problem and will need different load steps, but the load steps seem to not work.

IMAGE LINK: http://3466464376628175598-a-180274...75XmUX3nBhIDdG3_Rp8P-KWsuDyAzul4Z9abJsIm07A==

Two cylinder materials, as shown. The dimensions don't really matter all too much. I then want to have the initial temp at 0 then ramped to 1000 and constant for 3 hours and then back down to zero.

Also, if you know then how to run that same analysis over 800 cycles would be great.

Anything will help. I believe that it is going to be a transient problem and will need different load steps, but the load steps seem to not work.

IMAGE LINK: http://3466464376628175598-a-180274...75XmUX3nBhIDdG3_Rp8P-KWsuDyAzul4Z9abJsIm07A==