- #1

ligazetom

- 5

- 0

Hello everyone,

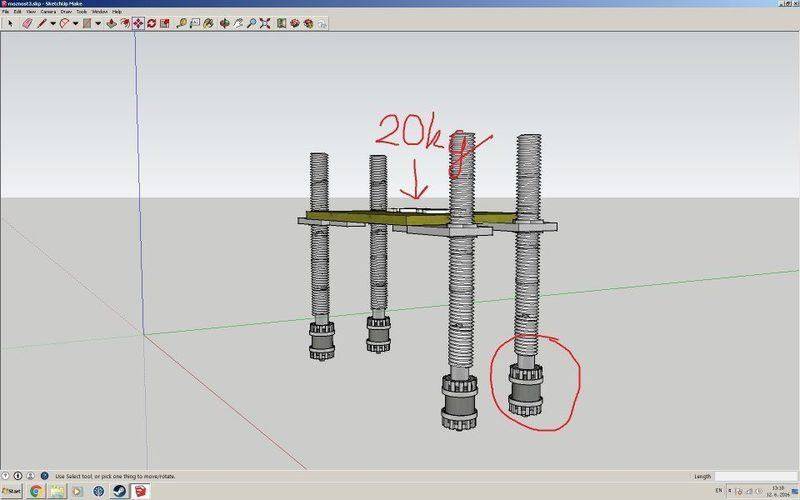

I want to build my own computer desk for past few years and soon I will have enough money to do so. What I am trying to do is make it look like normal desk and by pressing "THE"button all monitors will raise up from inside of it. I quickly sketched some mechanism so you can imagine what it will work like.

It is only example, not final stage component, however I don't know how much torque does one motor need to be able to spin. Let's say I have 20kg on top so, one motor has to push up 5kgs. Now I am lost. One revolution of screw should lift it 1cm. I don't really want just the answer, but how can I figure it out later myself with different variables. If anyone of you has even better idea of how it can work with different mechanism, I will appreciate every single one. Thank you for your replies.

It is only example, not final stage component, however I don't know how much torque does one motor need to be able to spin. Let's say I have 20kg on top so, one motor has to push up 5kgs. Now I am lost. One revolution of screw should lift it 1cm. I don't really want just the answer, but how can I figure it out later myself with different variables. If anyone of you has even better idea of how it can work with different mechanism, I will appreciate every single one. Thank you for your replies.

I want to build my own computer desk for past few years and soon I will have enough money to do so. What I am trying to do is make it look like normal desk and by pressing "THE"button all monitors will raise up from inside of it. I quickly sketched some mechanism so you can imagine what it will work like.