desquee

- 18

- 1

I've been building a 3 phase delta wired alternator. I recently cast the stator in fiberglass resin, and now i get no response from the terminals. Before casting, I used the multimeter's resistance setting to test the connections between each pair of the three terminals, and all registered a closed circuit. After casting the stator, no pair of terminals registered a closed circuit (I tried two different multimeters).

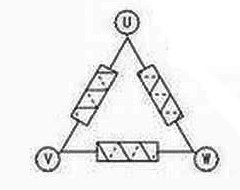

Since the stator is wired in a delta configuration, each pair of terminals are connected to each other independently of the other one. There are no visible breaks in the wires (the resin is partly transparent), and I can't think of how the casting process could have broken the circuit in at least three different places.

The wiring of the stator (simplified):

A picture of the stator after casting:

Does anyone have any ideas as to what might have gone wrong, or other tests I could do?

Does anyone have any ideas as to what might have gone wrong, or other tests I could do?

Since the stator is wired in a delta configuration, each pair of terminals are connected to each other independently of the other one. There are no visible breaks in the wires (the resin is partly transparent), and I can't think of how the casting process could have broken the circuit in at least three different places.

The wiring of the stator (simplified):

A picture of the stator after casting: