SUMMARY

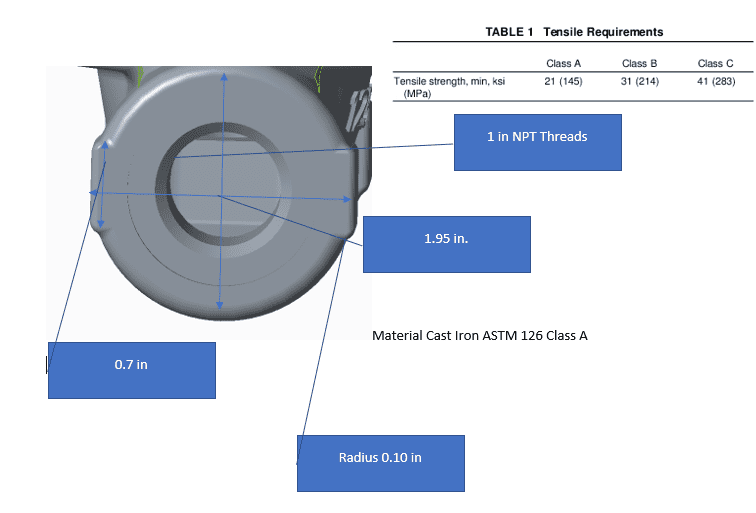

The maximum torque that can be applied to a 1-inch male threaded NPT pipe when connected to a 1-inch female threaded body made from ASTM 126 cast iron is not definitively established due to the variability in materials and conditions. Recommended assembly practices suggest using a pipe thread sealant and tightening until "it feels right," rather than relying on specific torque values. Industry standards provide guidelines for the number of turns past finger tight, but empirical testing is necessary to determine failure points. Manufacturers like Parker Hannifin provide resources for assembly recommendations, emphasizing the importance of practical experience in achieving leak-free connections.

PREREQUISITES

- Understanding of NPT (National Pipe Thread) standards

- Familiarity with ASTM 126 cast iron specifications

- Knowledge of torque application methods in mechanical assemblies

- Experience with pipe thread sealants and their applications

NEXT STEPS

- Research the effects of thread taper and quality on NPT connections

- Study Finite Element Analysis (FEA) methods for predicting failure points in threaded joints

- Investigate empirical studies on torque application for NPT fittings

- Review Parker Hannifin's assembly guidelines for NPT connections

USEFUL FOR

Engineers, plumbers, and maintenance professionals involved in the installation and assembly of NPT pipe fittings, as well as those seeking to optimize leak prevention in threaded connections.