rwooduk

- 757

- 59

Liquid is being pumped into a vessel then it leaves and recirculates through the pump. I have calibrated the pump by measuring the amount of fluid being pumped through the tube (not into the vessel).

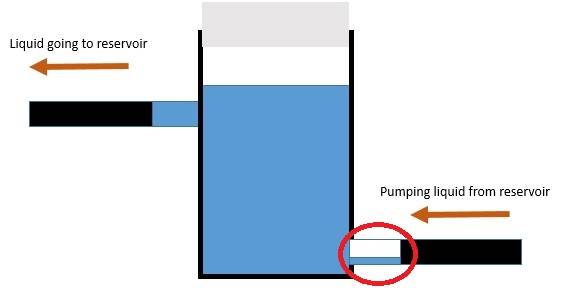

However I have noticed at low flow rates the liquid level at the inlet is only half full! That is it looks like this...

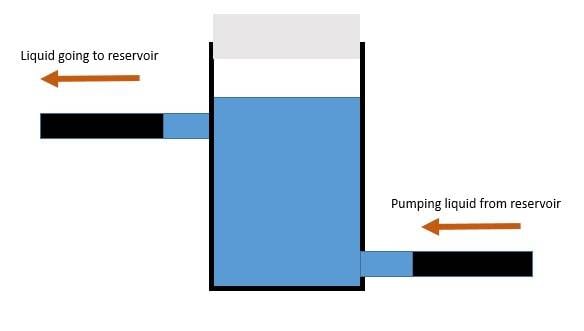

Instead of like this...

Does this indicate that the liquid is not being pumped into the solution in the vessel? Perhaps due to the pressure of weight of the fluid in the vessel??

Its a peristaltic pump so there is no reservoir, just a tube that is connected to the inlet and outlet with the pump in between.

What does the gap mean is happening? Why isn't it full of fluid?

Thanks for any help figuring this out, I've done experiments at low flow rate with the pump set to low values and I am concerned that its not pumping into the solution due to pressure.

However I have noticed at low flow rates the liquid level at the inlet is only half full! That is it looks like this...

Instead of like this...

Does this indicate that the liquid is not being pumped into the solution in the vessel? Perhaps due to the pressure of weight of the fluid in the vessel??

Its a peristaltic pump so there is no reservoir, just a tube that is connected to the inlet and outlet with the pump in between.

What does the gap mean is happening? Why isn't it full of fluid?

Thanks for any help figuring this out, I've done experiments at low flow rate with the pump set to low values and I am concerned that its not pumping into the solution due to pressure.