mg-eng

- 2

- 0

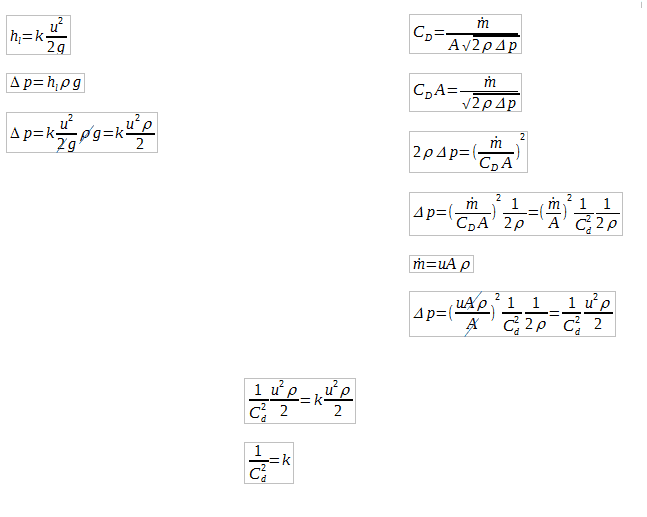

What is relationship between discharge coefficient and minor loss coefficient. Am I right with that equations?

hl – minor head loss

k – minor loss coefficient

ρ – air density

A – pipe cross section area

Cd – discharge coefficient

Δp – pressure drop

u – air velocity

m – mass flow

here is written that it is true:

https://neutrium.net/fluid_flow/discharge-coefficient-for-nozzles-and-orifices/

https://en.wikipedia.org/wiki/Discharge_coefficient

but what with case when k <= 1 ?

hl – minor head loss

k – minor loss coefficient

ρ – air density

A – pipe cross section area

Cd – discharge coefficient

Δp – pressure drop

u – air velocity

m – mass flow

here is written that it is true:

https://neutrium.net/fluid_flow/discharge-coefficient-for-nozzles-and-orifices/

https://en.wikipedia.org/wiki/Discharge_coefficient

but what with case when k <= 1 ?