- #1

rollingstein

Gold Member

- 646

- 16

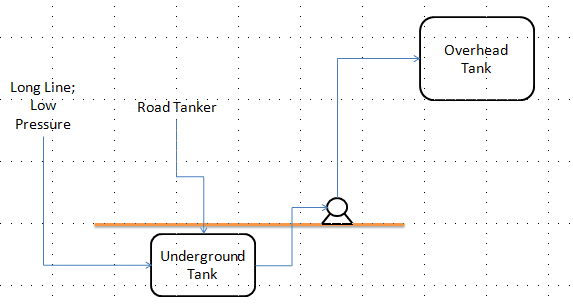

I have a water tank fed from a piping system that has very low head in it. As a result flow tends to be low. See sketch below. I am thinking of ways to boost the flow. I already have a centrifugal pump at the site. Could I use its flow to boost the flow from the incoming pipe via a venturi / ejector design?

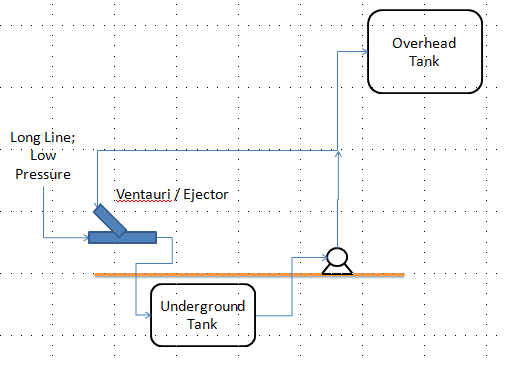

As a DIY project what might be a good way of creating the venturi? Would a simple tee work? Or would I need a converging diverging nozzle (e.g. see the sketch below)? Any ideas how to chose the nozzle dimensions?

As a DIY project what might be a good way of creating the venturi? Would a simple tee work? Or would I need a converging diverging nozzle (e.g. see the sketch below)? Any ideas how to chose the nozzle dimensions?