From out in the real world -

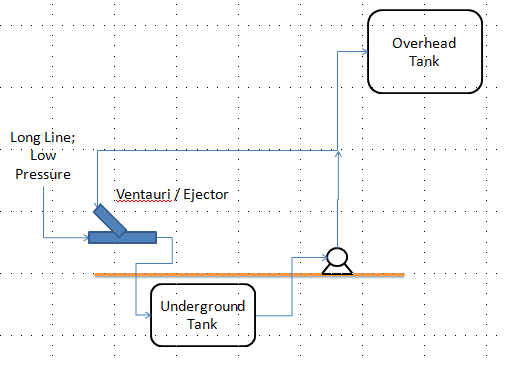

I played around with suction dredges for hobby gold mining for 30 years. Net water lift in that application is only about 12 inches but additional suction is needed to bring up beercan-sized rocks with enough velocity that they don't stall in the intake hose or stack up and jam in the area beyond the venturi.

For a suction dredge assuming a primary pipe diameter of 2 to 4 inches and a centrifugal pump of 1.5 to 5 hp, I found after a lot of experimentation that water pressure a little over 30 psi and a jet orifice of 5/8 inch is optimum. Keene Engineering sells 'Power Jets' for $100 that will save you a lot of cut-n-try engineering. Recommended, for what you are trying to accomplish.

http://www.keeneeng.com/mm5/merchant.mvc?Store_Code=KES&Screen=CTGY&Category_Code=PJ

Now I'm considering making a venturi system like you describe, to speed up the gravity-feed filling of the tank I tow around to water new orchard trees. Lift is negative, the trailer is slightly lower than the storage tank, but I want to minimize fill time.

Perhaps someone smarter than me can present the math needed for optimum design. Simply based on experience, it seems to me that you don't want a reduced diameter in the pipe beyond the jet. For gasses a reduction may improve the 'traction' that the jet applies to push the medium. But water is incompressible and has inertia, so a reduction in diameter seems to me to reduce efficiency. In fact the additional water added by the jet has to pass that area, another argument for not reducing the diameter. Undetermined is how long the pipe has to be downstream from the jet, for the energy from the jet to be imparted uniformly to the entire amount of water in the moving column. I think Keene's jets mentioned above are generally too short for maximum efficiency feeding the intake of a gold sluice box. At least in my own designs optimized for backpacking, there was sometimes water at greater velocity recognizable in the output to the sluice box, indicating that not all the force from the jet had been applied to the column of water.

When you figure out an optimum solution for your application I would love to see it, and apply it here to my watering rig!