Discussion Overview

The discussion revolves around the purpose of the metal fin-like structures found on LED bulbs, specifically addressing whether they function as heat sinks and the implications of heat management in LED technology compared to incandescent bulbs.

Discussion Character

- Technical explanation

- Conceptual clarification

- Debate/contested

Main Points Raised

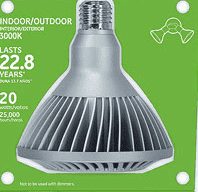

- Some participants suggest that the metal fins are indeed heat sinks, necessary for cooling LEDs due to their sensitivity to high temperatures, which can reduce light output and affect longevity.

- Others argue that conventional incandescent bulbs do not require heat sinks because their design allows for heat retention, which is essential for their operation.

- One participant explains that while LEDs convert more electrical energy to light than incandescent bulbs, they still produce heat that must be dissipated to prevent damage, thus necessitating cooling mechanisms like fins.

- Another participant notes that the thermal management in incandescent bulbs relies on thermal radiation rather than non-radiative heat sinks, questioning the necessity of heat sinks in LED designs.

Areas of Agreement / Disagreement

Participants express differing views on the necessity and function of heat sinks in LED bulbs compared to incandescent bulbs. There is no consensus on the role of the fins, with some supporting their importance for cooling while others challenge the need for such mechanisms.

Contextual Notes

The discussion includes various assumptions about the efficiency of light production and heat management in different bulb technologies, as well as the implications of altitude on heat dissipation for LEDs.