- #1

ChessEnthusiast

- 115

- 3

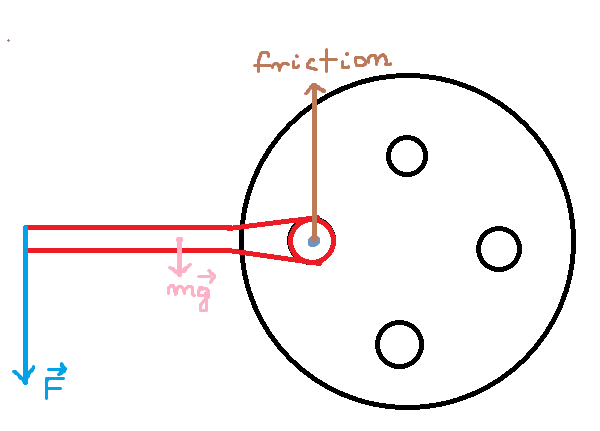

Let's say we want to change a wheel in a car. We want to remove bolts fastening the wheel using this tool:

I have also drawn a diagram of the forces in operation:

Now, from experience I can say that the point of rotation of the wrench will be the blue point. Now, trying to determine the torque relative to that point leaves us with a net torque anticlockwise (friction gets canceled out).

Yet, we know that removing these bolts requires some effort. Therefore, there either are more forces in action or the axis of rotation I chose is incorrect (or both)

What am I missing?

I have also drawn a diagram of the forces in operation:

Now, from experience I can say that the point of rotation of the wrench will be the blue point. Now, trying to determine the torque relative to that point leaves us with a net torque anticlockwise (friction gets canceled out).

Yet, we know that removing these bolts requires some effort. Therefore, there either are more forces in action or the axis of rotation I chose is incorrect (or both)

What am I missing?