zephyrific

- 1

- 0

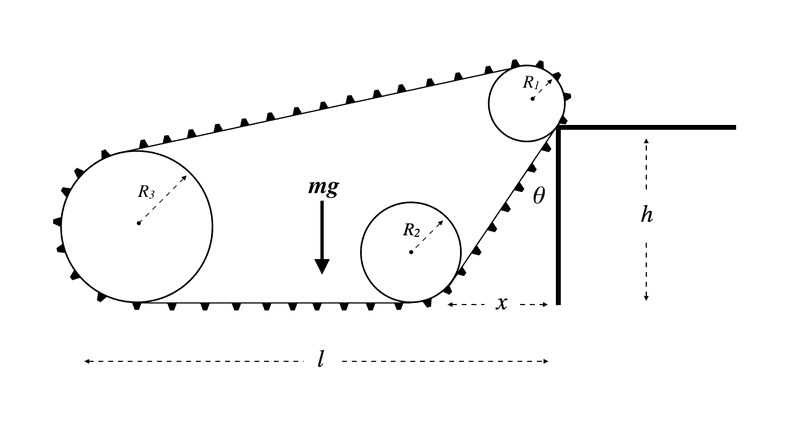

I'm trying to figure out whether it is best to use a multi-wheel or track system to get an object over a step, however I'm having a bit of trouble finding the torque needed for a track to pull itself up and over.

Diagram of course is not to scale, but I've drawn up something of the situation. I'm not sure of whether to consider the radius of the wheel in contact with the step or rather the track as a whole, or if I'm approaching this completely incorrectly.

Also, to clarify, the weight would be distributed across each point of contact with the ground, and also the point of contact with the step, correct?

Diagram of course is not to scale, but I've drawn up something of the situation. I'm not sure of whether to consider the radius of the wheel in contact with the step or rather the track as a whole, or if I'm approaching this completely incorrectly.

Also, to clarify, the weight would be distributed across each point of contact with the ground, and also the point of contact with the step, correct?