nickvasallo

- 3

- 0

Hello everyone,

I am a music composer and total noob. So please excuse my lack of engineering knowledge.

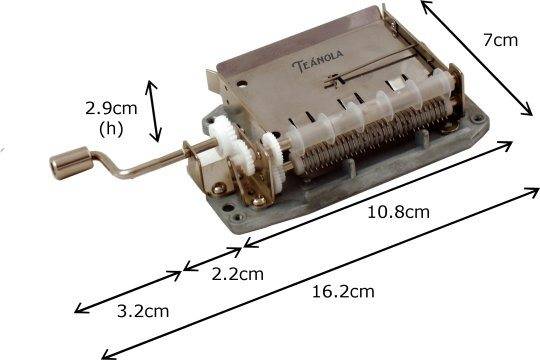

I am attempting to build a music box that can play without having to turn the gear's crankshaft manually. Here is a picture of the music box:

I have been doing some research and think I have a rough plan. Please correct me if I am wrong, I think I need a DC motor like this one:

http://www.sciplus.com/itm_photos/web40663.jpg

Do you guys think this is a good motor to turn the gears? I also want to be able to change the speed so I guess I'll need a rheostat or potentiometer. Which is better and what specs do I need? Will I need to match the voltage of my motor?

What batteries are good for this? I would like to save space so if I get two 9 volts = 18V will this be too much for my little 12V motor?

Is there a good package kit that has a motor and speed control together?

thanks ahead of the help and advice!

I am a music composer and total noob. So please excuse my lack of engineering knowledge.

I am attempting to build a music box that can play without having to turn the gear's crankshaft manually. Here is a picture of the music box:

I have been doing some research and think I have a rough plan. Please correct me if I am wrong, I think I need a DC motor like this one:

http://www.sciplus.com/itm_photos/web40663.jpg

This nominal 12VDC gear motor measures 1-1/16" dia (1-5/16" at the gearbox) x 2-1/16" long with a 3/8" long x 3/16" dia flattened shaft. Spins at 135 rpm and draws 35mA no load, stalls at 1A. Has a 2-pin, 6mm Molex connector at the power leads.

Do you guys think this is a good motor to turn the gears? I also want to be able to change the speed so I guess I'll need a rheostat or potentiometer. Which is better and what specs do I need? Will I need to match the voltage of my motor?

What batteries are good for this? I would like to save space so if I get two 9 volts = 18V will this be too much for my little 12V motor?

Is there a good package kit that has a motor and speed control together?

thanks ahead of the help and advice!

Last edited by a moderator: